ABOUT US

Cattaruzzi S.R.L. is a leader in the design, construction and installation of equipment for chicken slaughtering plants.

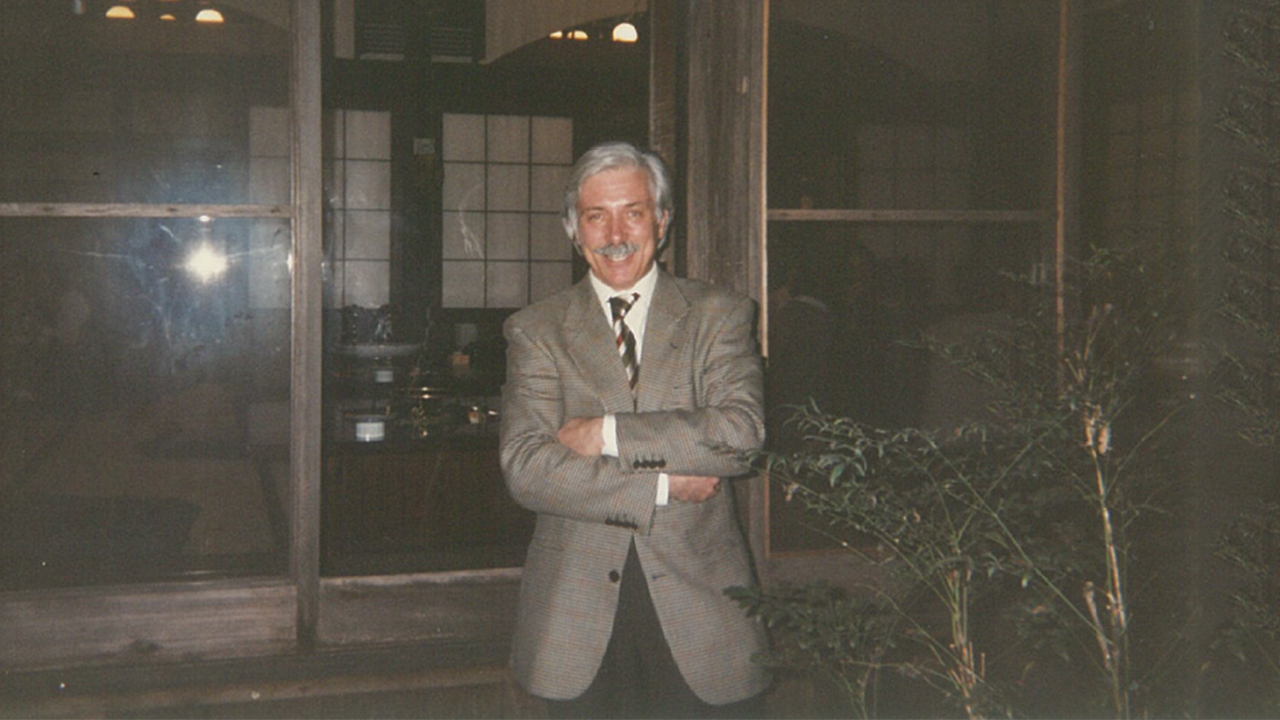

The Cattaruzzi company was founded by Guido Cattaruzzi who started the business by building slaughtering plants for small farms.

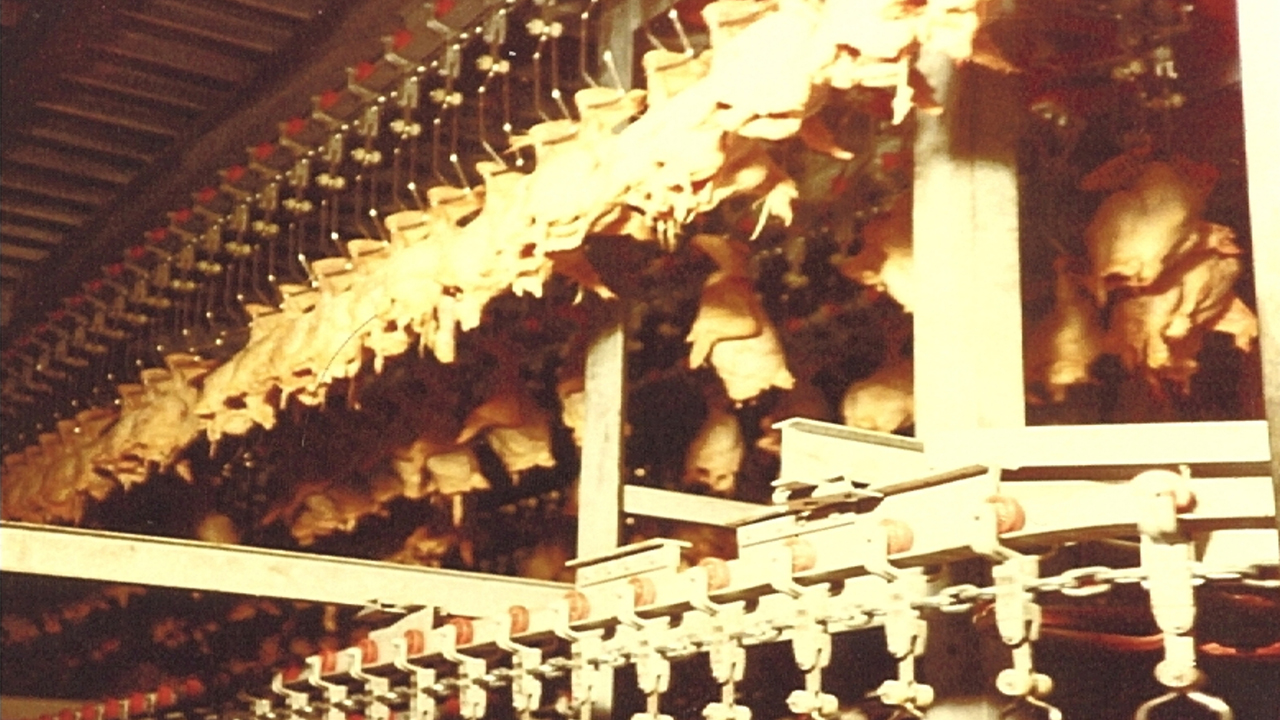

In 1960 in Italy Cattaruzzi installed the first automation line for the slaughter of chickens at the Polli Arena company.

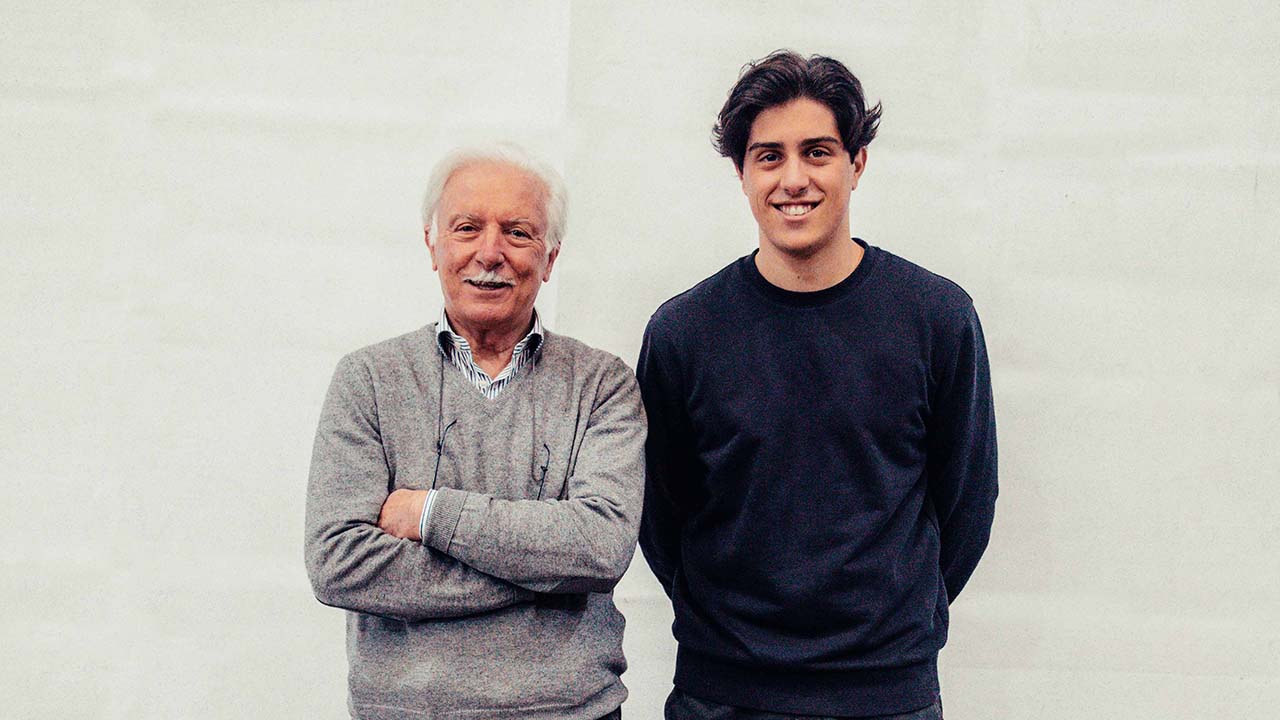

Guido's son, engineer Bruno Cattaruzzi, joined the company. Thus the company underwent considerable development from a technological point of view, in fact, in addition to the first cutting line, the first complete automation line was designed and developed.

In 1976 Guido and Bruno began construction of the new factory in San Zeno Naviglio of about 5,000 square meters.

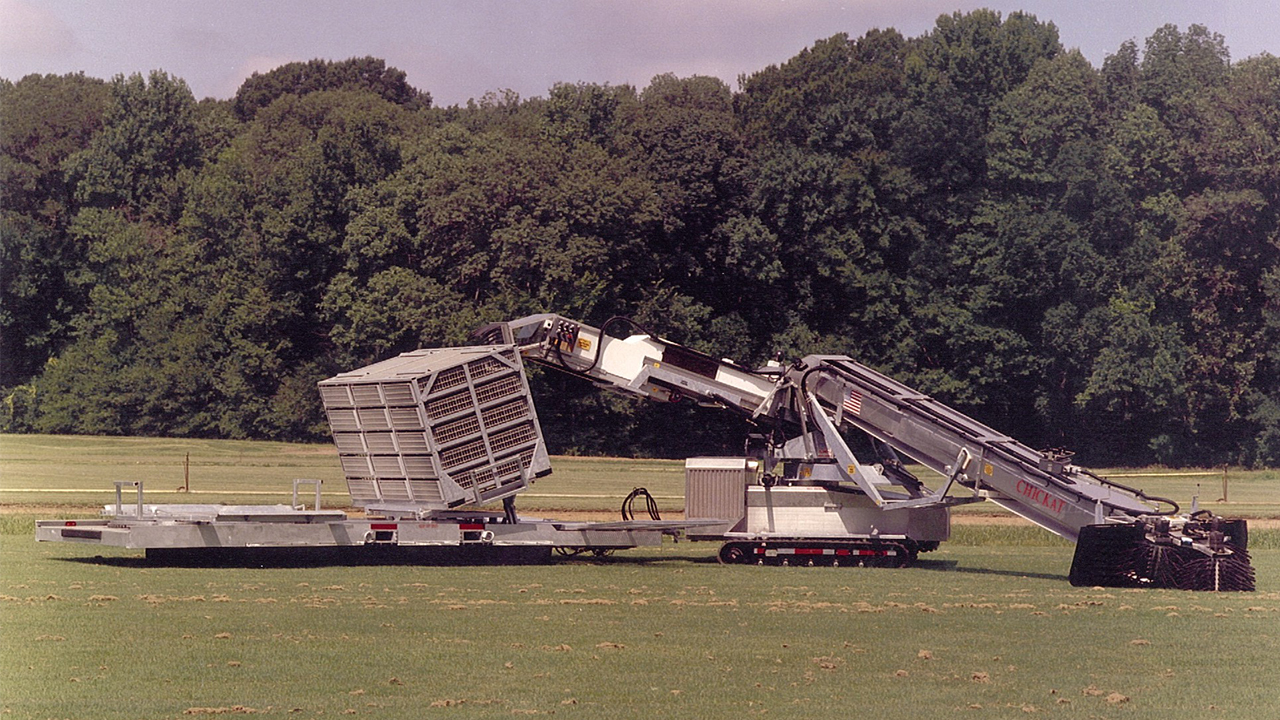

The first Chicken Catcher machine was built on a patent, and in the following years over 90 machines were built and sold, most of them sold in America.

Commissioned by the Pavo factory, the longest single-shackle cooling tunnel of the time was built, measuring 4,170 m.

Since 2006 the company has been able to produce every single slaughter, evisceration, cooling and cutting machine in its own factory.

In 2015, the son of Bruno Cattaruzzi, Giacomo, joined the company and currently holds the role of sales engineer within the company.

COMPANY

The plant is located in San Zeno Naviglio, a few kilometers from the Brescia Centro A4 motorway exit.

It was designed by Guido and Bruno Cattaruzzi in 1976 and has a covered area of 5,000 m² on an area of approximately 10,000 m².

Inside, the plant is divided into specific areas for raw materials, for machinery in the production and assembly phase and for the packaging and shipping of finished products.

A large area has been set aside for the spare parts warehouse.

The offices and services are a separate body and occupy an area greater than 400 m².

The offices have recently been renovated and expanded.