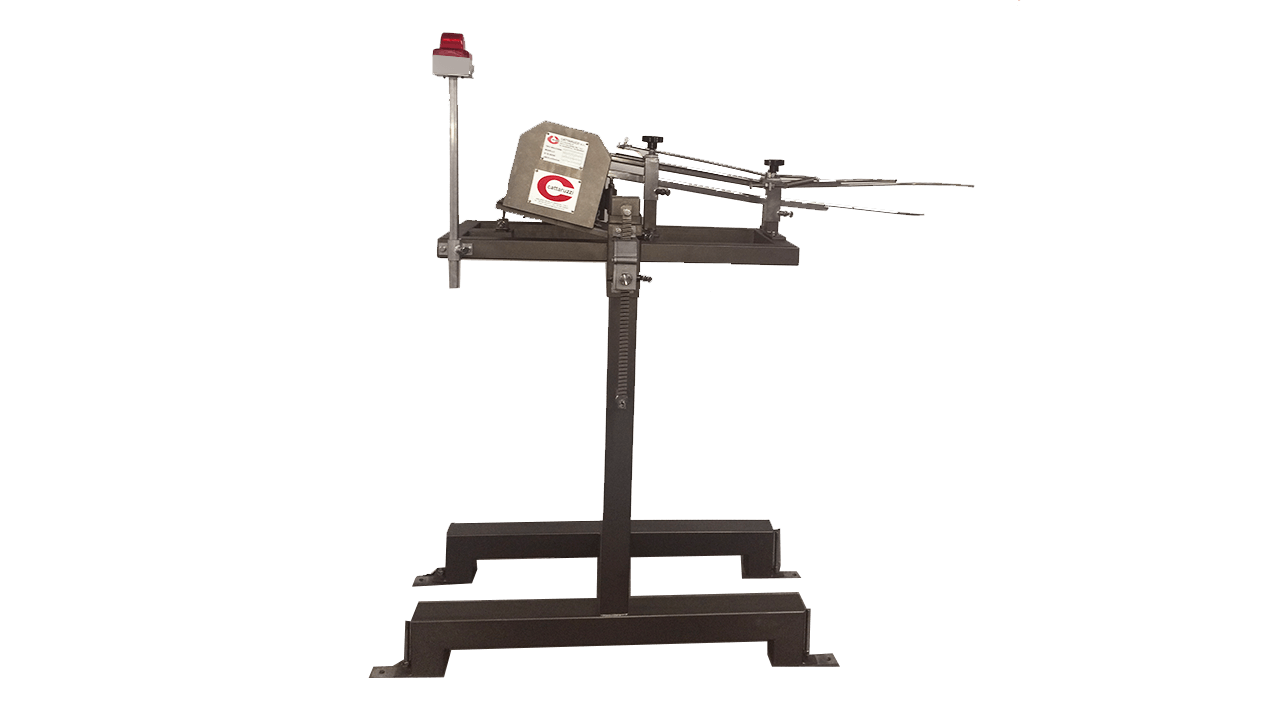

EVISCERATION

This machine cuts the head of the chickens. It can be installed on any kind of killing line and it is suitable for any capacity. It does not require to be synchronised with the overhead conveyor. The structure guide-bars are made of stainless steel.

| Capacity | 8.000 | B/h |

|---|---|---|

| Lenght | 1.150 | mm |

| Width | 650 | mm |

| Height | 800 | mm |

| Power installed | 0,55 | kw |

| Total weight | 110 | kg |

| Shipping volume | 0,6 | M³ |

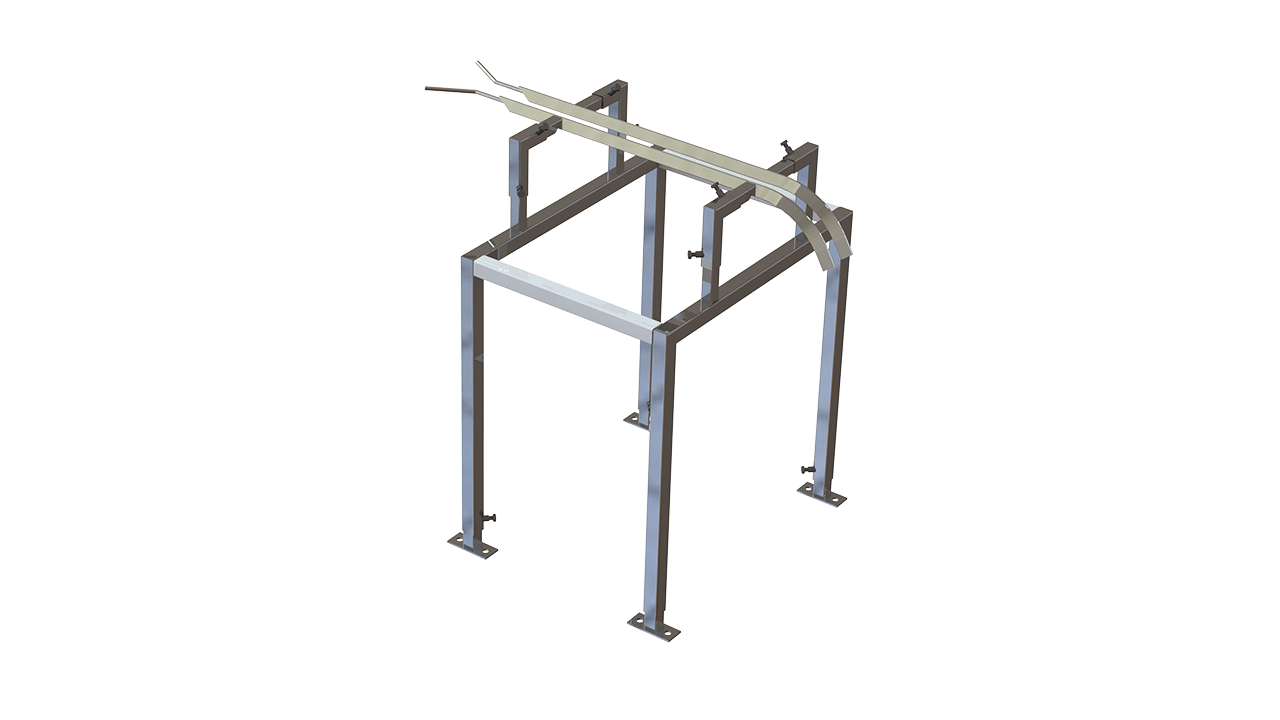

EVISCERATION

This machine removes the chickens head. It can be installed on any kind of killing or eviscerating line. It does not require to be synchronised with the overhead conveyor. The structure guide-bars are made of stainless steel.

| Capacity | 4.000 | B/h |

|---|---|---|

| Lenght | 1.150 | mm |

| Width | 720 | mm |

| Height | 800 | mm |

| Total weight | 30 | kg |

| Shipping volume | 0,2 | M³ |

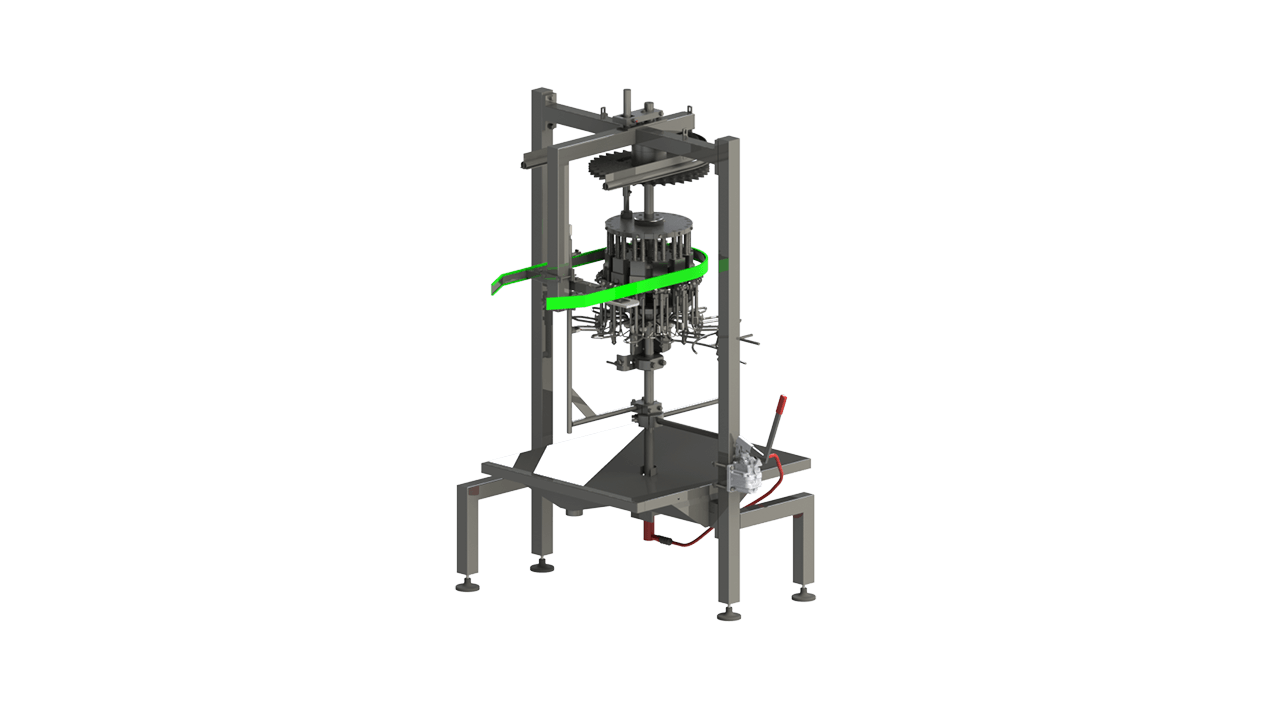

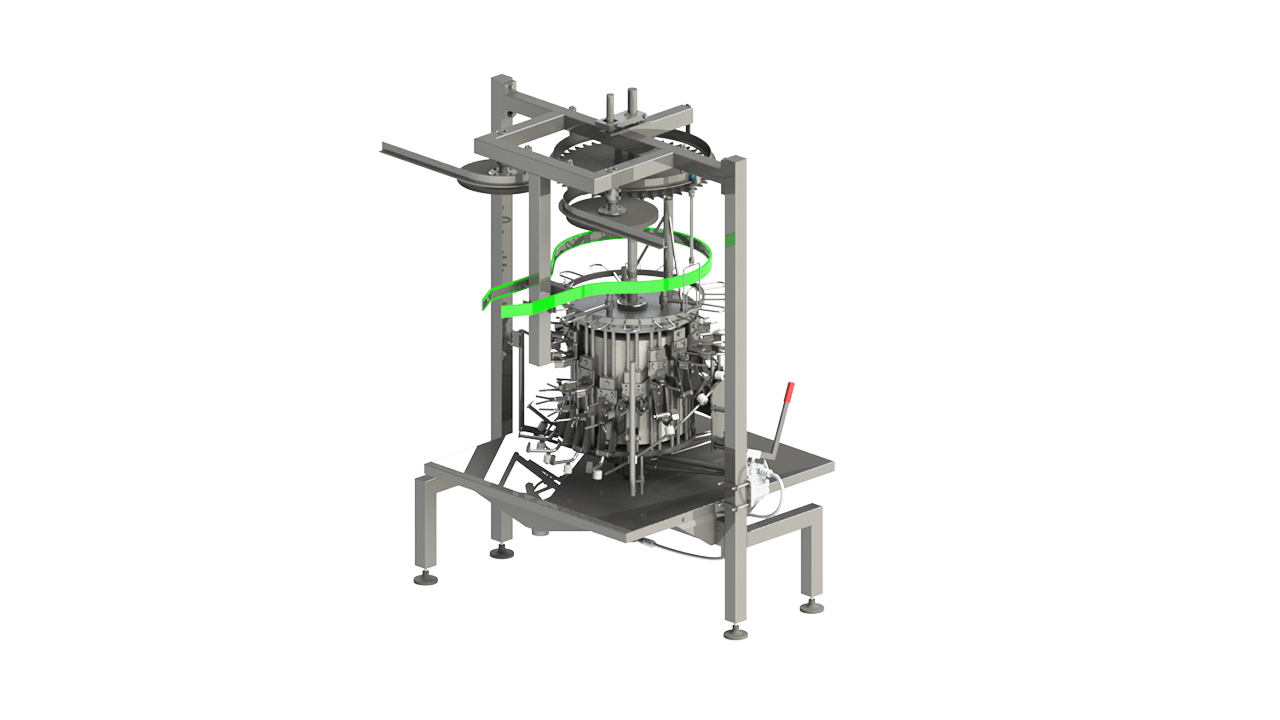

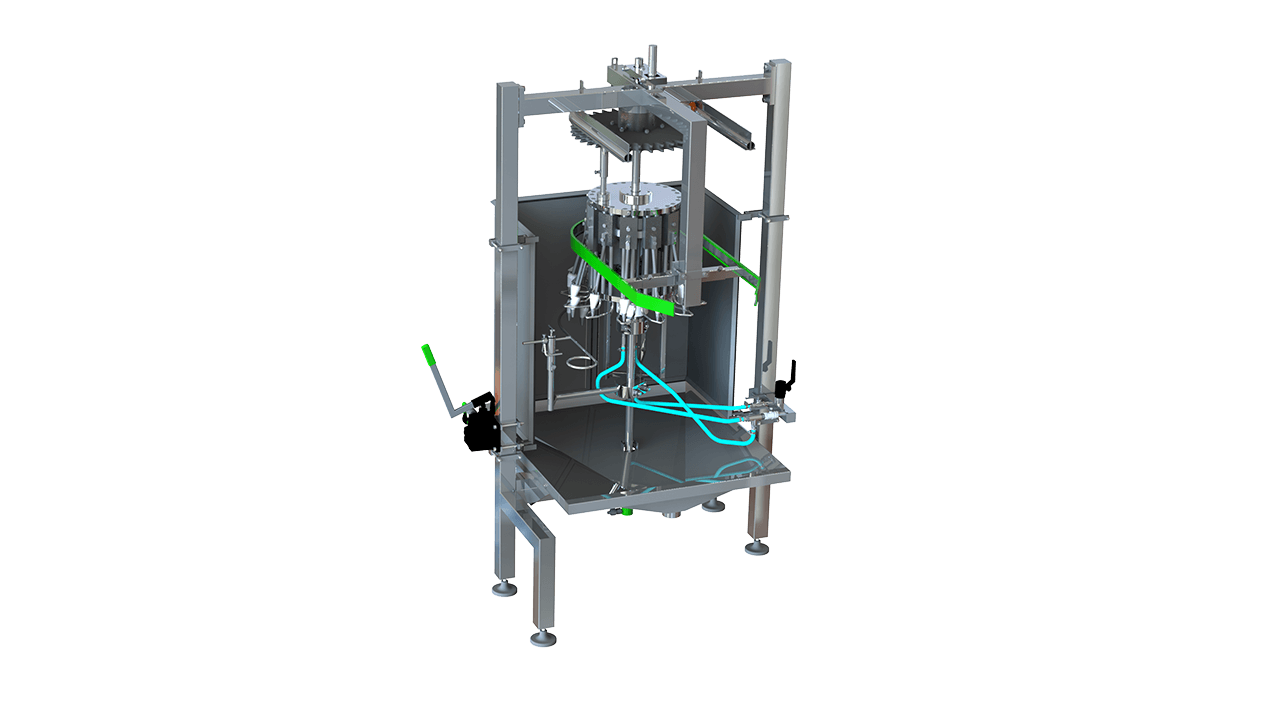

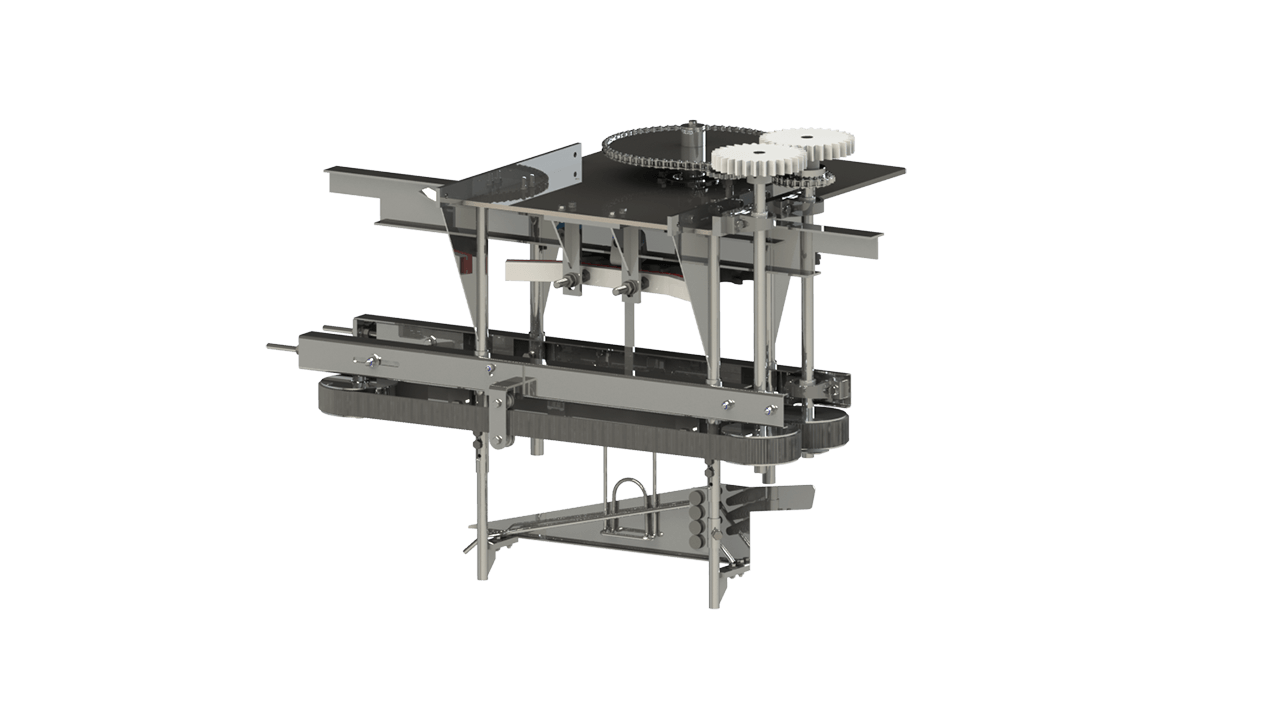

EVISCERATION

The Vent Cutter removes the vent from the chicken by producing a circular cut around the vent. After cutting ,the vent and bursa is lifted out of the bird by a pin and released outside the tail on the back of the chicken. No vacuum is required. The chickens are positioned into the machine below the blade by special clamping unit, self adjusting according to the size of the birds. The rotation of the circular blades is controlled by a set of gears driven by the machine itself. A hand operated stainless steel hydraulic jack raise and lower the machine allowing adjustment for flock variations. Machine is made of stainless steel and food approved nylon.

| Capacity | 6.000 | B/h |

|---|---|---|

| Lenght | 1.960 | mm |

| Width | 1.720 | mm |

| Height | 2.940 | mm |

| Water cons. at 3 bar | 350 | l/h |

| Power installed | 1,5 | kw |

| Total weight | 1.400 | kg |

| Shipping volume | 7 | M³ |

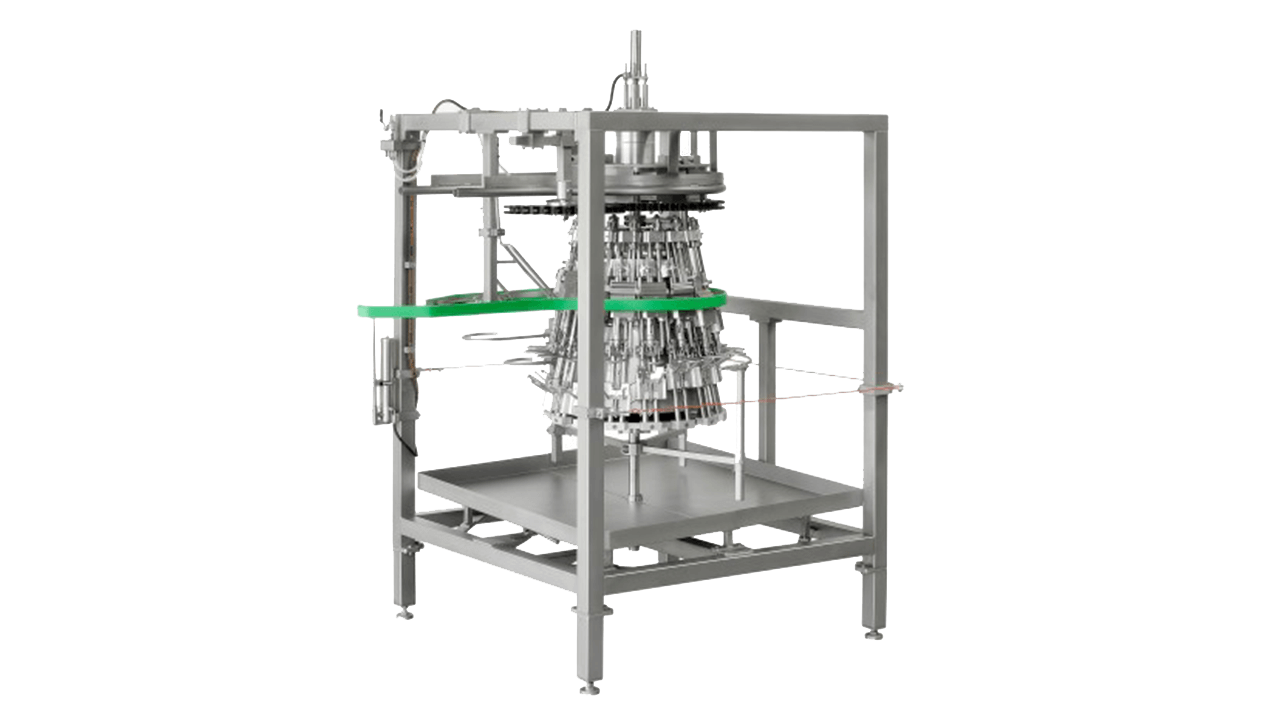

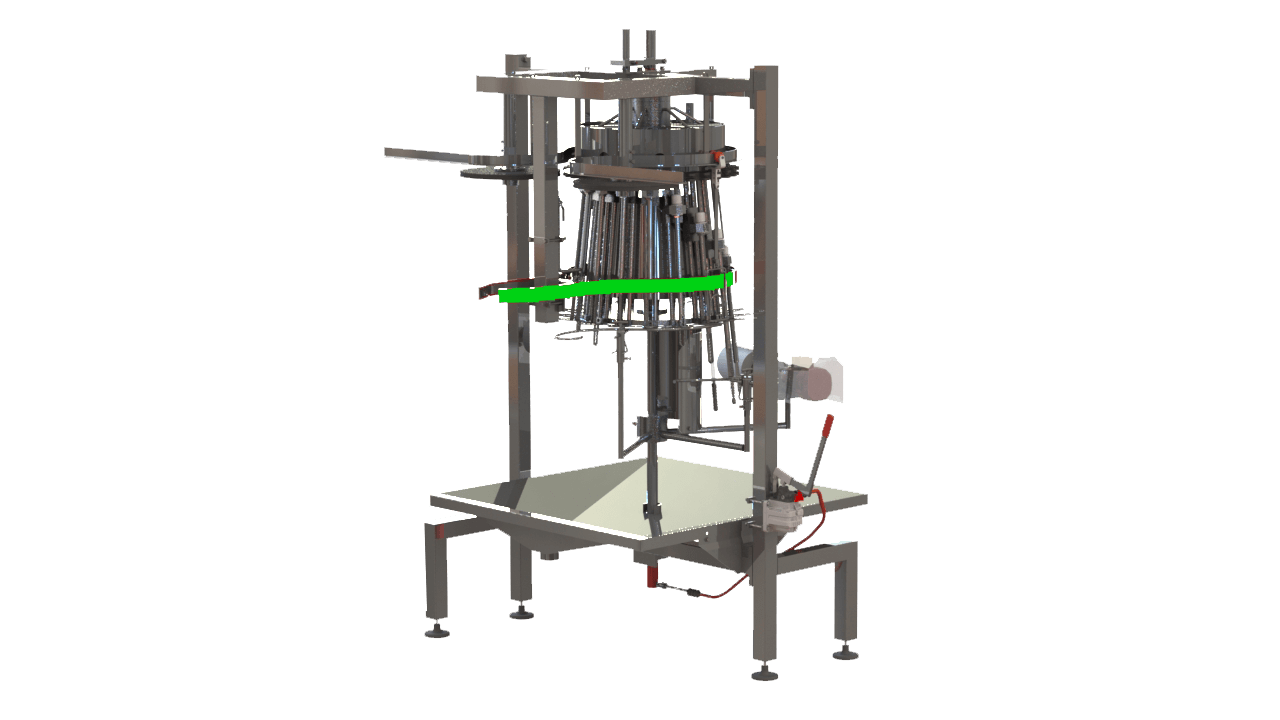

EVISCERATION

The automatic opening machine is designed to open the vent by cutting the skin up to the breast point of the birds. The length of the cut is easily adjustable according to the size of the birds. The machine is made of stainless steel and nylon.

| Model | 12U | 16U | |

|---|---|---|---|

| Capacity | 3.000 | 6.000 | B/h |

| Lenght | 900 | 1.385 | mm |

| Width | 1.160 | 1.280 | mm |

| Height | 2.330 | 2.250 | mm |

| Water cons. at 3 bar | 1,5 | 2 | l/h |

| Total weight | 250 | 350 | kg |

| Shipping volume | 2,3 | 3,5 | M³ |

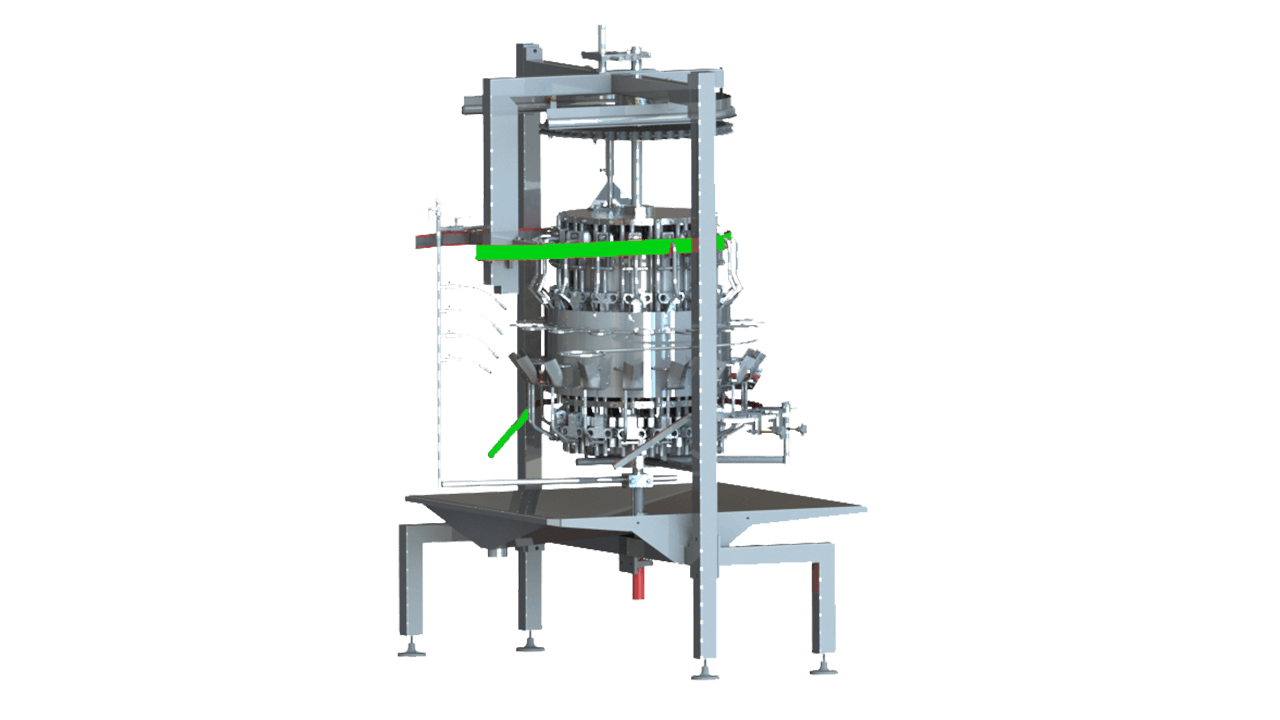

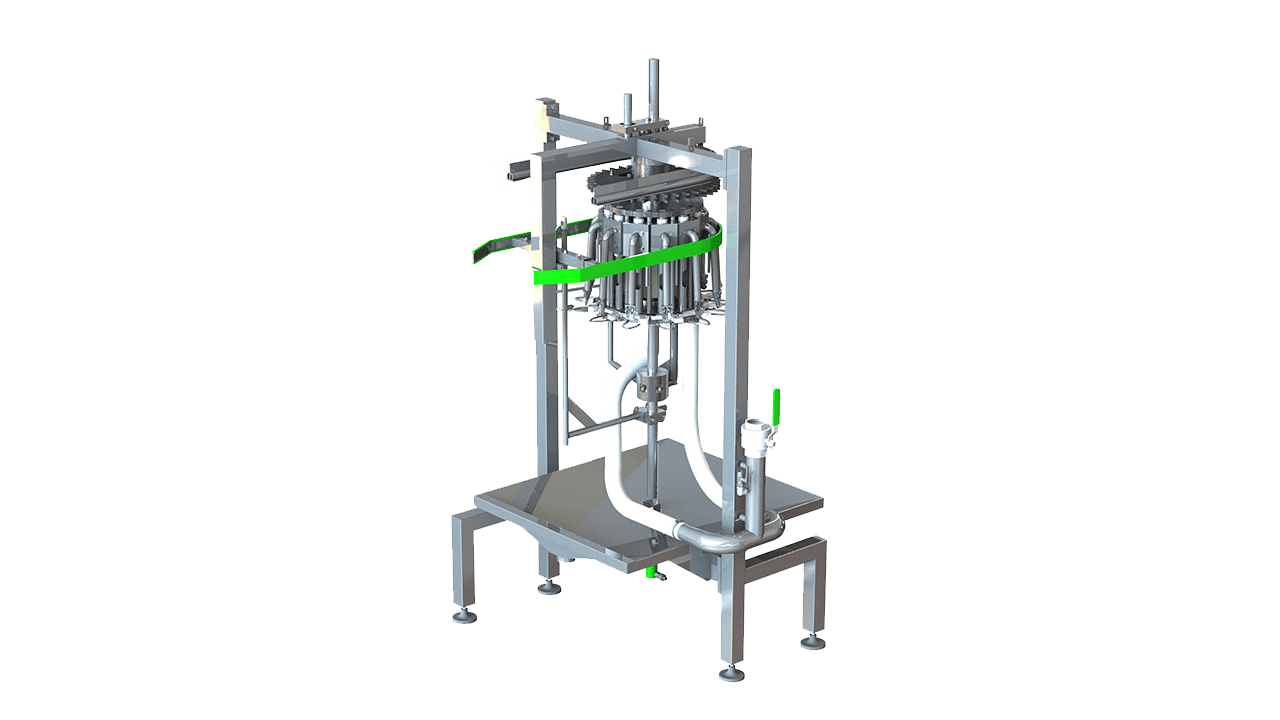

EVISCERATION

The automatic eviscerator is designed to remove by a special spoon driven by a solid plastic cam, the intestine from the birds. It is driven by the overhead conveyor and is made of stainless steel.

| Capacity | 6.000 | B/h |

|---|---|---|

| Lenght | 1.385 | mm |

| Width | 1.600 | mm |

| Height | 2.250 | mm |

| Water cons. at 3 bar | 350 | l/h |

| Total weight | 680 | kg |

| Shipping volume | 5,2 | M³ |

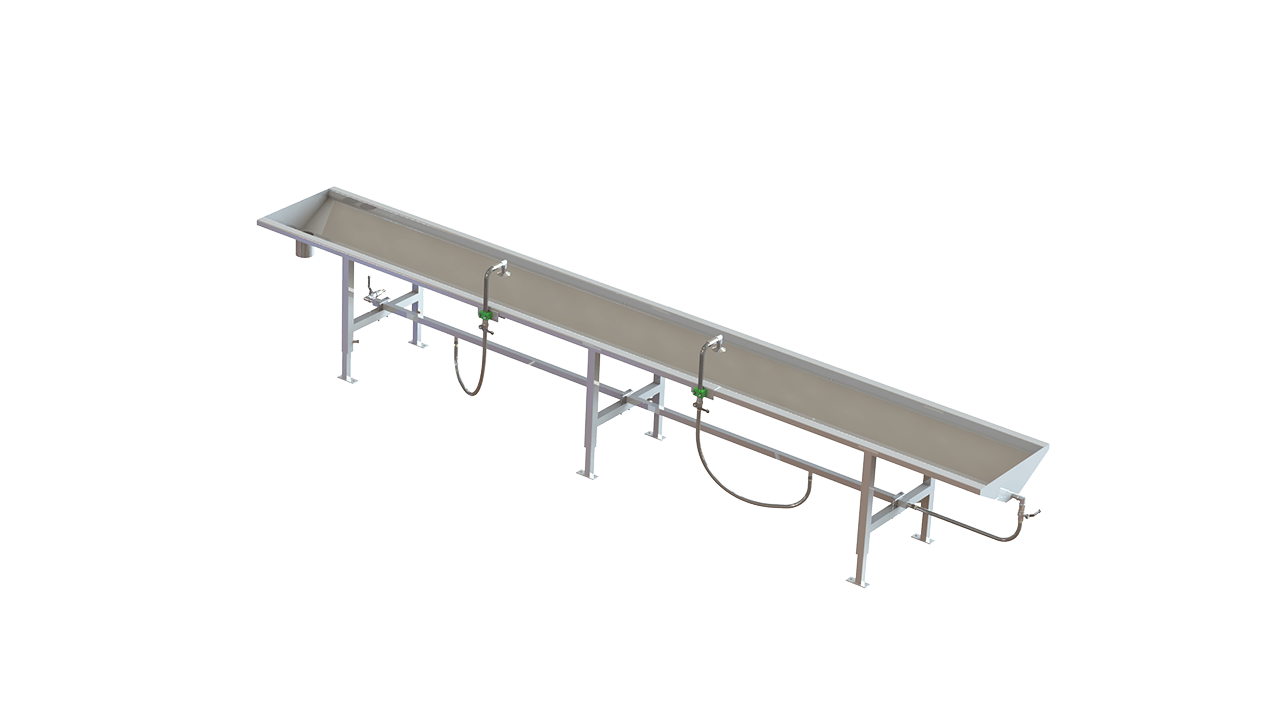

EVISCERATION

The evisceration through is used to collect all intestines and waste coming from the evisceration. The through is composed of 2000mm stainless steel sections and gutter for the giblets.

| Model | SR | DR | |

|---|---|---|---|

| Lenght | 2.000 | 2.000 | mm |

| Width | 500 | 800 | mm |

| Height | 700 | 700 | mm |

| Water cons. at 3 bar | 0,5 | 0,5 | l/h |

| Total weight | 40 | 70 | kg |

| Shipping volume | 0.9 | 1,1 | M³ |

EVISCERATION

The automatic cropping machine is used to remove the crops and clean the necks of the birds. Special rotating tools enter the birds’ cavities and push the crop of the bird outside . A rotating brush cleans the tools at the end of the cycle. The machine is built in st. steel.

| Capacity | 3.000 | B/h |

|---|---|---|

| Lenght | 1.350 | mm |

| Width | 1.620 | mm |

| Height | 2.370 | mm |

| Water cons. at 3 bar | 1,5 | l/h |

| Power installed | 0,75 | kw |

| Total weight | 500 | kg |

| Shipping volume | 5,1 | M³ |

EVISCERATION

This machine has been designed to remove automatically the whole neck of the birds with or without the skin. All the parts of this machine are in stainless steel and non‑toxic plastic.

| Model | 12U | 16U | |

|---|---|---|---|

| Capacity | 3.000 | 6.000 | B/h |

| Lenght | 1.680 | 1.680 | mm |

| Width | 1.050 | 1.250 | mm |

| Height | 2.250 | 2.250 | mm |

| Water cons. at 3 bar | 1,12 | 1,12 | l/h |

| Total weight | 500 | 600 | kg |

| Shipping volume | 4 | 4,47 | M³ |

EVISCERATION

The automatic in-out bird washer is a machine equipped with special nozzles to properly wash inside end outside the birds.

The machine is built in stainless steel and nylon solid cam.

| Model | 12U | 16U | |

|---|---|---|---|

| Capacity | 3.000 | 6.000 | B/h |

| Lenght | 980 | 980 | mm |

| Width | 1.160 | 1.160 | mm |

| Height | 2.250 | 2.250 | mm |

| Water cons. at 3 bar | 3 | 4 | l/h |

| Total weight | 250 | 300 | kg |

| Shipping volume | 2,4 | 3,7 | M³ |

EVISCERATION

This machine positioned at the end of the eviscerating line washes out side the birds thanks to two rotating axes with rubber’s fingers and efficient water sprayers. The frame and protections are made of stainless steel. The brushes are moved by separated motorgearbox.

| Capacity | 6.000 | B/h |

|---|---|---|

| Lenght | 1.200 | mm |

| Width | 800 | mm |

| Height | 1.400 | mm |

| Water cons. at 3 bar | 1 | l/h |

| Power installed | 0,74 | kw |

| Total weight | 140 | kg |

| Shipping volume | 1 | M³ |

EVISCERATION

The bird spray washer washes the bird outside by means of spraying nozzles. The frame is made of stainless steel.

| Capacity | 6.000 | B/h |

|---|---|---|

| Lenght | 750 | mm |

| Width | 1.150 | mm |

| Height | 1.800 | mm |

| Water cons. at 3 bar | 2 | l/h |

| Total weight | 70 | kg |

| Shipping volume | 0,6 | M³ |

EVISCERATION

This automatic final control machine is used to suck by vacuum all the loose pieces and lungs from the birds cavity. The machine is built in stainless steel and the cam is made of solid nylon.

| Model | 12U | 16U | |

|---|---|---|---|

| Capacity | 3.000 | 6.000 | B/h |

| Lenght | 970 | 1.150 | mm |

| Width | 1.260 | 1.260 | mm |

| Height | 2.250 | 2.250 | mm |

| Water cons. at 3 bar | 1,5 | 1,5 | l/h |

| Vacuum usage | 400 | 600 | m³/h |

| Total weight | 450 | 500 | kg |

| Shipping volume | 2,8 | 3,5 | M³ |

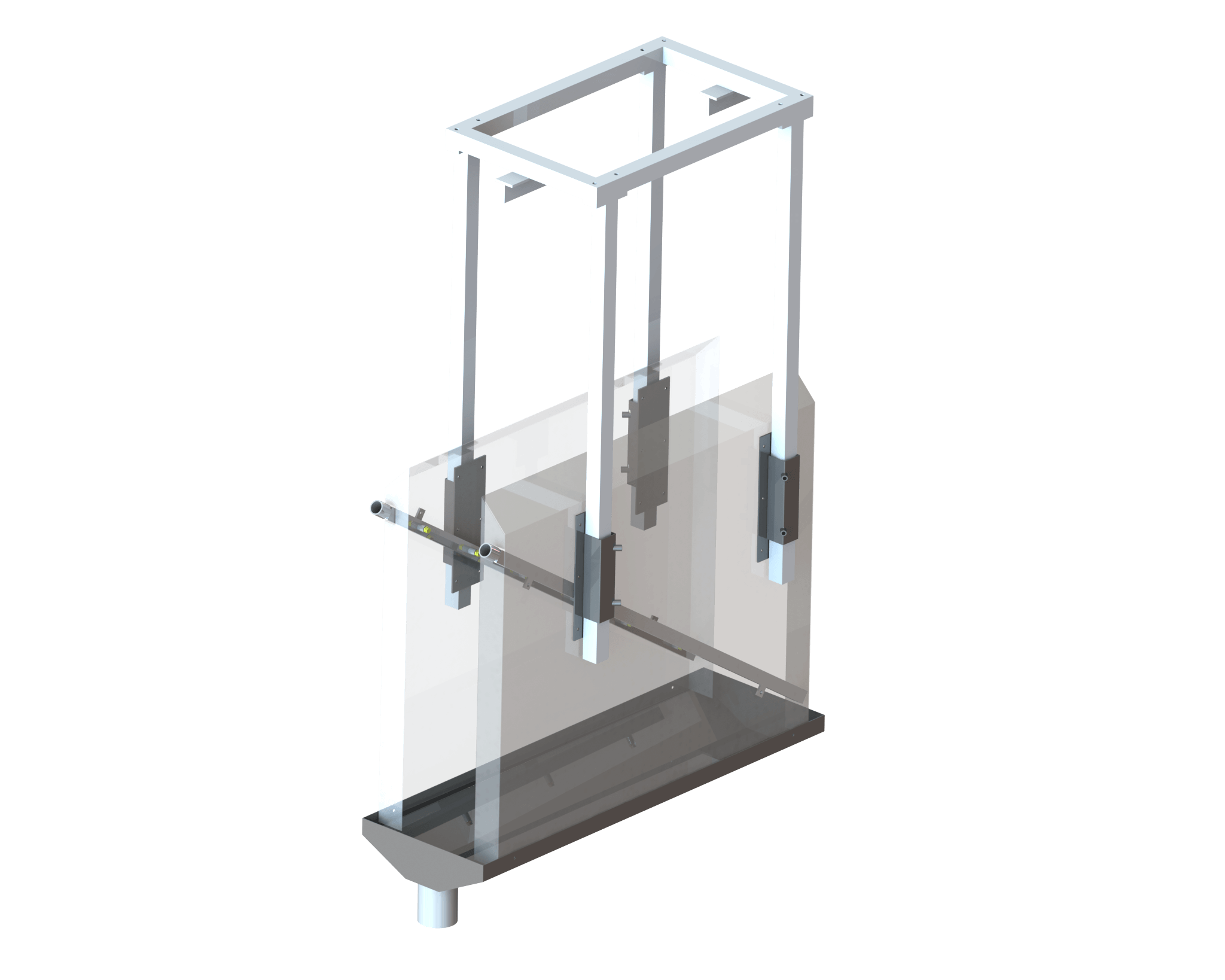

EVISCERATION

The automatic bird unloader is a machine drive by the overhead conveyor and placed at the end of the eviscerating line. A special toothed rubber belts, block and drive the shackles during the unloading of the birds. The machine is made of stainless steel.

| Capacity | 8000 | B/h |

|---|---|---|

| Lenght | 800 | mm |

| Width | 950 | mm |

| Height | 2.250 | mm |

| Total weight | 140 | kg |

| Shipping volume | 1 | M³ |

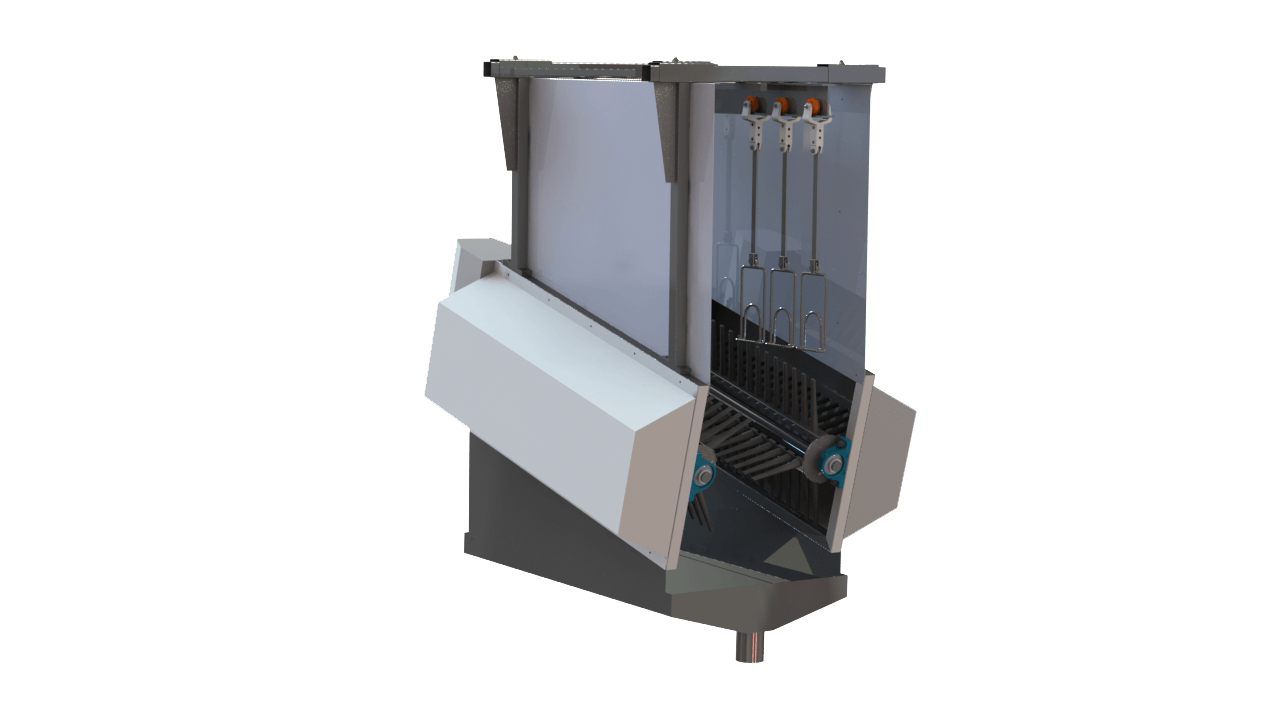

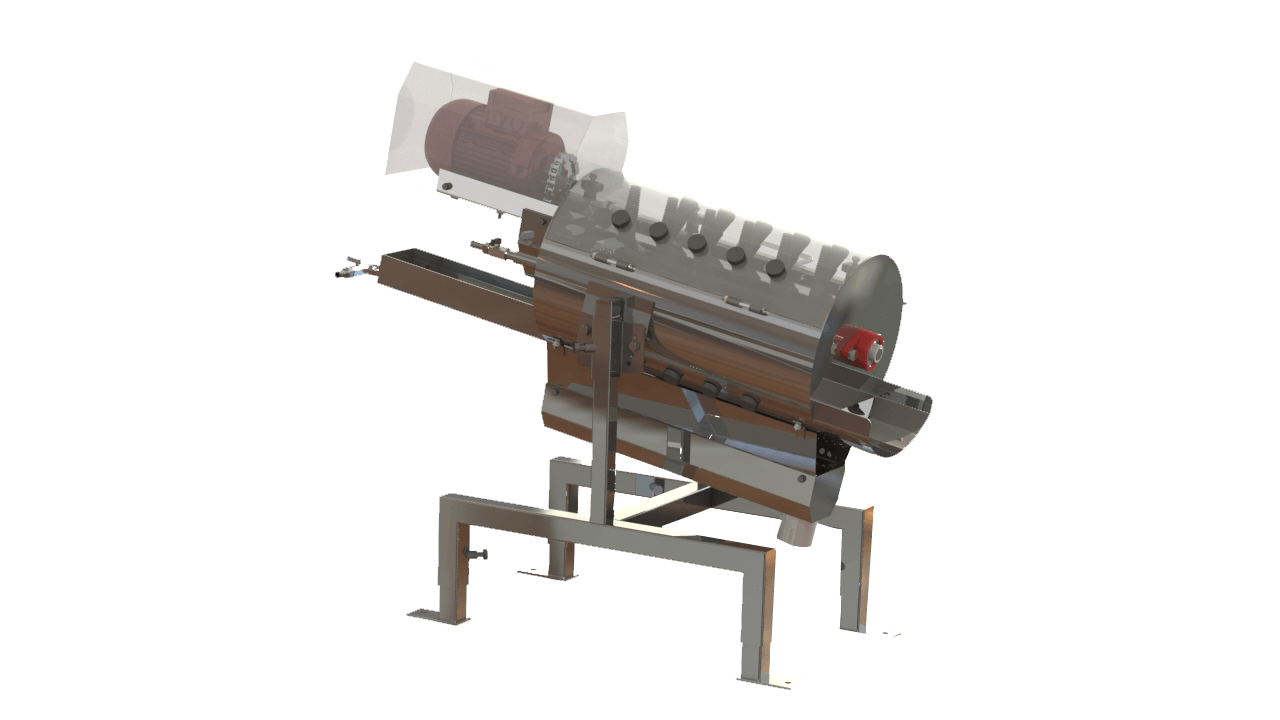

EVISCERATION

The gizzard splitter and peeler made of stainless steel, first opens and washes the stomachs and than peels the inner skin. The machine include manual control peeler roller.

| Capacity | 3.000 | B/h |

|---|---|---|

| Lenght | 2.000 | mm |

| Width | 800 | mm |

| Height | 1.100 | mm |

| Water cons. at 3 bar | 1,5 | m³/h |

| Power installed | 2,55 | kw |

| Total weight | 215 | kg |

| Shipping volume | 1,7 | M³ |

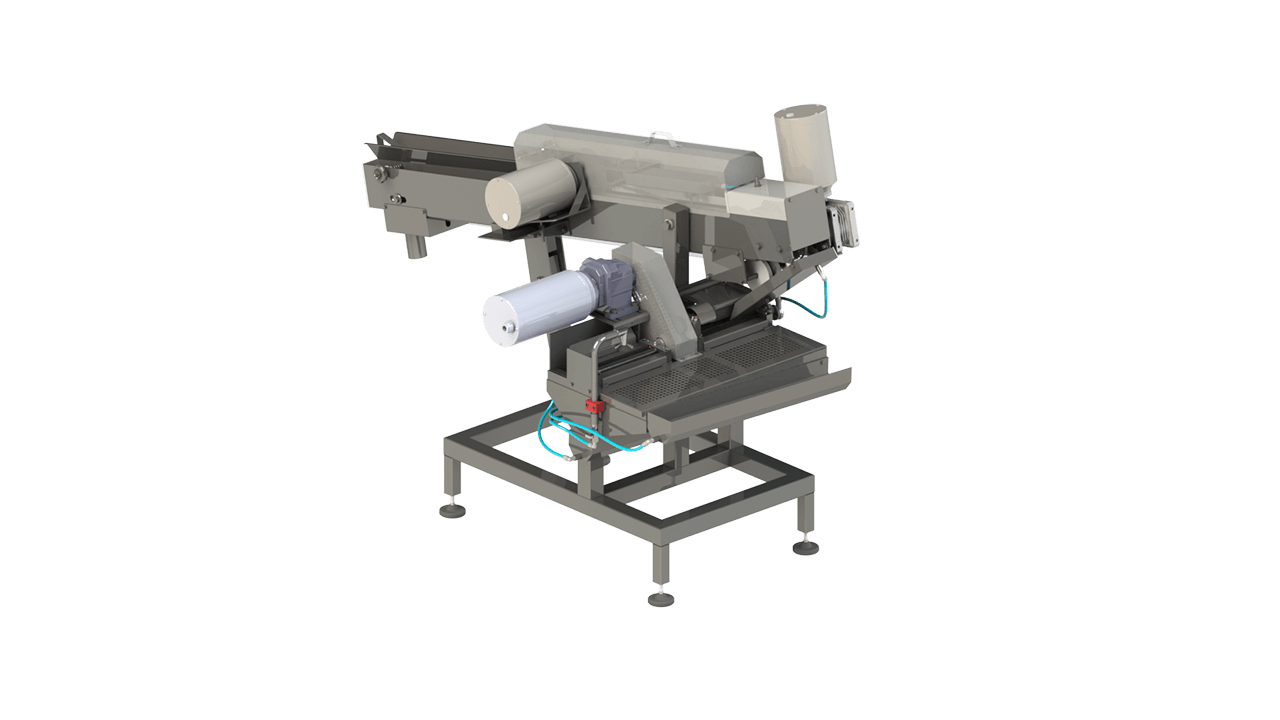

EVISCERATION

The gizzard splitter and peeler made of stainless steel. first remove the intestine from the stomach then opens and washes the stomachs and peels the inner skin.

| Capacity | 8.000 | B/h |

|---|---|---|

| Lenght | 2.300 | mm |

| Width | 900 | mm |

| Height | 1.050 | mm |

| Water cons. at 3 bar | 3 | m³/h |

| Power installed | 4,05 | kw |

| Total weight | 550 | kg |

| Shipping volume | 2 | M³ |

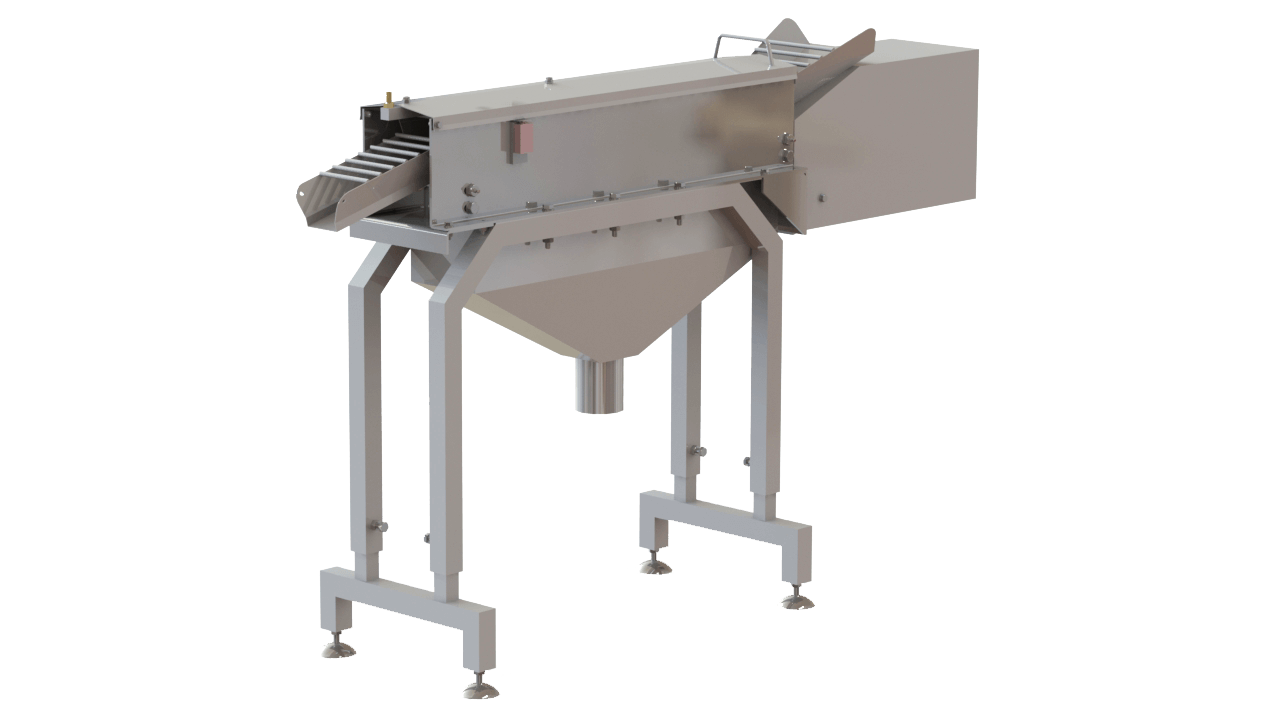

EVISCERATION

The gizzard separator is able to perfectly separate the gizzards from the viscera after hearts and livers have been removed by the operator.

This machine has frame covers and shafts made of stainless steel.

| Capacity | 6.000 | B/h (1 operator) |

|---|---|---|

| Lenght | 1.600 | mm |

| Width | 400 | mm |

| Height | 950 | mm |

| Water cons. at 3 bar | 0,5 | m³/h |

| Power installed | 0,75 | kw |

| Total weight | 86 | kg |

| Shipping volume | 0,6 | M³ |

EVISCERATION

This machine made of stainless steel removes the fat from the gizzard trough the action of rubber fingers, fixed on the frame and on a rotating shaft, and sprayed water.

| Capacity | 8.000 | B/h |

|---|---|---|

| Lenght | 1.000 | mm |

| Width | 450 | mm |

| Height | 700 | mm |

| Water cons. at 3 bar | 1 | m³/h |

| Power installed | 0,25 | kw |

| Total weight | 54 | kg |

| Shipping volume | 0,2 | M³ |

EVISCERATION

It is used to peel the inner skin of the gizzard by means of specially designed contra-rotating steel rollers driven by a motor-gearbox. The machine is made of stainless steel.

| Capacity | 8.600 | B/h (1 operator) |

|---|---|---|

| Lenght | 950 | mm |

| Width | 530 | mm |

| Height | 900 | mm |

| Water cons. at 3 bar | 1 | m³/h |

| Power installed | 0,75 | kw |

| Total weight | 63 | kg |

| Shipping volume | 0,5 | M³ |

EVISCERATION

This machine can be used in several points of the processing plant especially for lifting the livers, the gizzards, the heard and the necks to the collecting table. The machine is made of stainless steel.

| Capacity | 9.000 | B/h |

|---|---|---|

| Lenght | 1.350 | mm |

| Width | 150 | mm |

| Water cons. at 3 ba | 0,50 | m³/h |

| Power installed | 0,37 | kw |

| Total weight | 60 | kg |

| Shipping volume | 0,8 | M³ |

EVISCERATION

This diaphragm pump moves giblets from evisceration to chilling line. The pump is complete with stainless steel hoppers and air connection. It’s made of casting aluminium body.

| Capacity | 5.000 | l B/h |

|---|---|---|

| Lenght | 400 | mm |

| Width | 750 | mm |

| Height | 600 | mm |

| Pump head pressure | 6 | m |

| Inlet-outlet | 3″ | ich |

| Air pressure | 6 | bar |

| Total weight | 50 | kg |

| Shipping volume | 0,35 | M³ |

QUESTIONS?

Are you looking forward to start your new project?

Contact us and we will find the right solution for you.