CHILLING AND WEIGHING

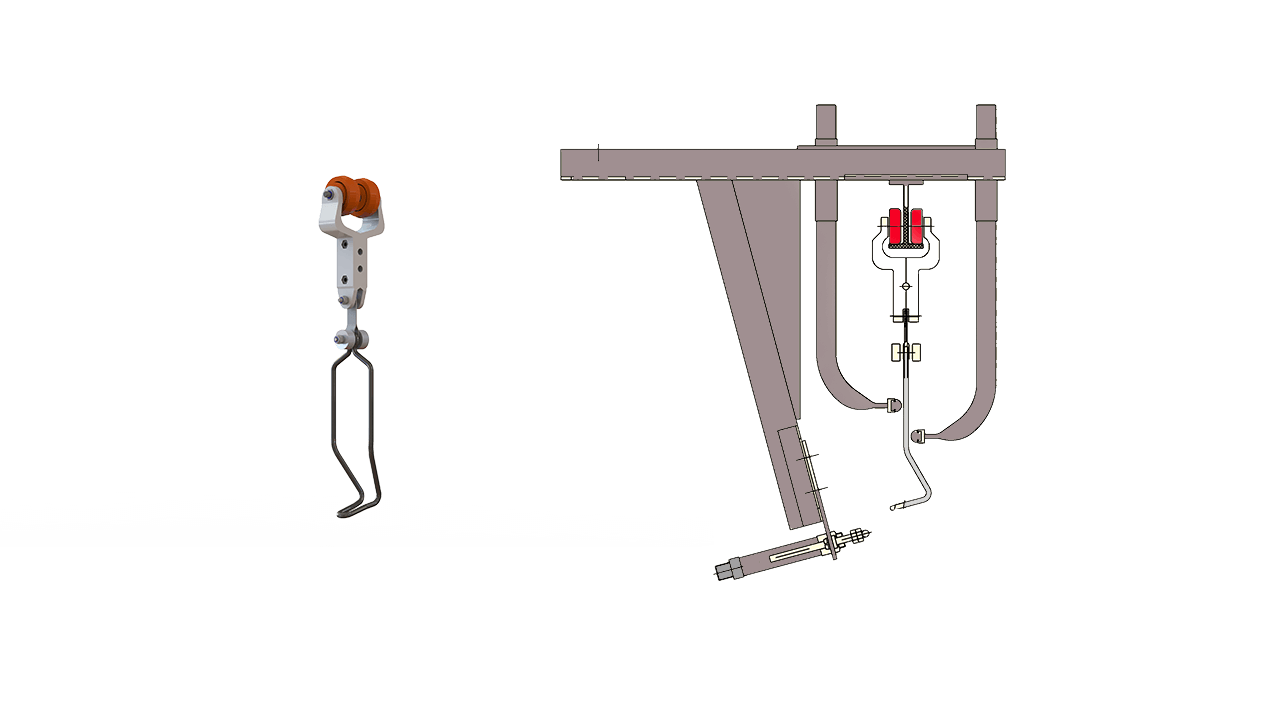

The air chiller is designed to lower the temperature of the eviscerated birds from about +38° C to approximately +2°/4° C by forced cooled air. The birds are hung on different types of multi birds carriers according to necessities, the capacity of the plant and the space available.

CHILLING AND WEIGHING

The air chiller is designed to lower the temperature of the eviscerated birds from about +38° C to approximately +2°/4° C by forced cooled air. The birds are hung on different types of multi birds carriers according to necessities, the capacity of the plant and the space available.

| Model | 24 | 27 | |

|---|---|---|---|

| Lenght | 400 | 400 | mm |

| Width | 180 | 180 | mm |

| Height | 1.280 | 1.440 | mm |

| Net weight approx. | 5,5 | 7 | kg |

| Shipping volume | 4,5 | 5 | m³ |

| Model | 30 | 51 | |

|---|---|---|---|

| Lenght | 400 | 400 | mm |

| Width | 180 | 180 | mm |

| Height | 1.600 | 1.600 | mm |

| Net weight approx. | 8 | 14 | kg |

| Shipping volume | 5,5 | 7 | m³ |

CHILLING AND WEIGHING

The weighing bridge is complete with a weighing cell, weight transmitter, wiring and all sensor needed. The frame is made of stainless steel.

| Capacity | 12.000 | b/h |

|---|---|---|

| Lenght | 1.800 | mm |

| Width | 260 | mm |

| Height | 680 | mm |

| Total weight | 30 | kg |

| Shipping volume | 0,7 | M³ |

CHILLING AND WEIGHING

The grading and weighing system “Aexi” is today the most technically advanced system to program and control the production into the poultry processing plant. It can be installed on separate weighing lines, or on existing dripping line or on a single bird chilling line. The data coming from the weighing bridge are sent to the computer which give all the information needed. All the parameter regarding the min.-max. weight for each station can be easily changed and showed on screen.

The most important are: Speed of the line. Total daily number of birds process. Total daily weights of birds process. Total number of birds dropped in each beams. Total weight of birds in each drop-off. Capacity up to 10.000 b/h at 8″ center shackles. Drop-off number: up to 16/32 weight selections.

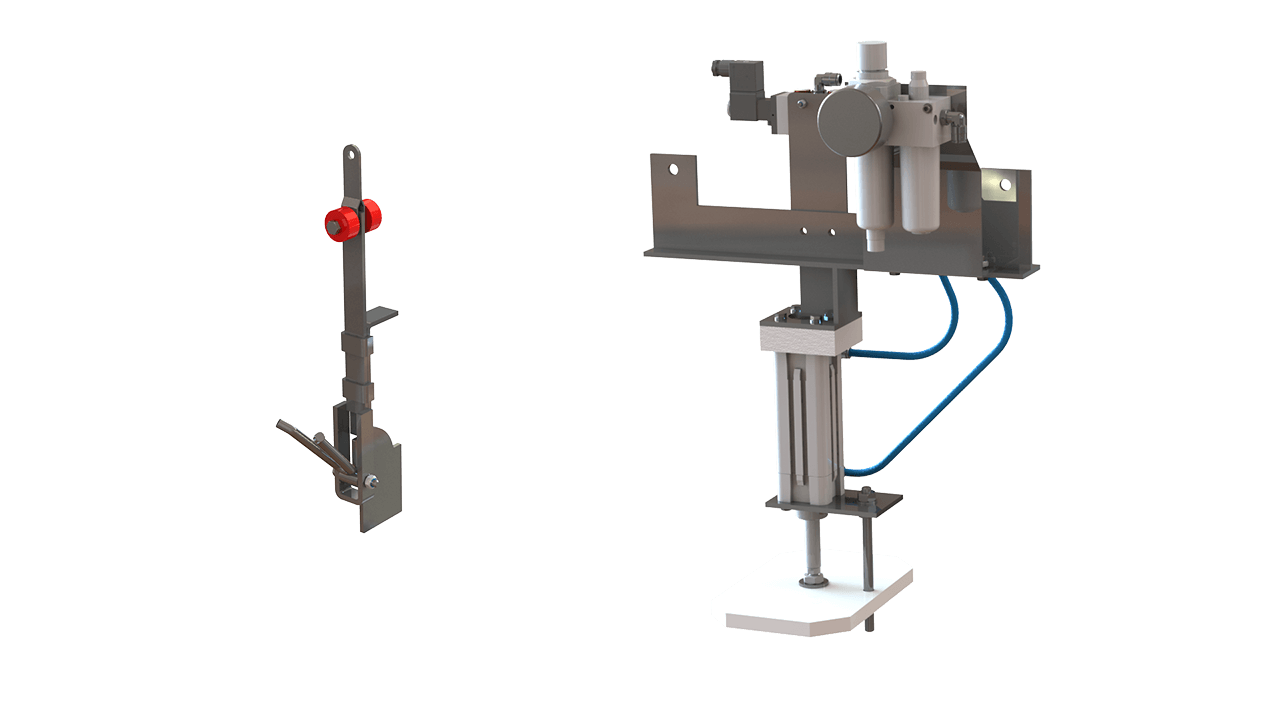

CHILLING AND WEIGHING

This unit consists of a pneumatic cylinder activated by an electro-valve. The drop off is complete with frame to be bolted to the overhead conveyor and all necessary pneumatic and electrical fittings.

| Lenght | 685 | mm |

|---|---|---|

| Width | 140 | mm |

| Height | 540 | mm |

| Air cons. | 0,7 | m³/h |

| Total weight | 77 | kg |

| Shipping volume | 0,42 | M³ |

CHILLING AND WEIGHING

This unit consists of a pneumatic cylinder activated by an electro-valve. The drop off is complete with frame to be bolted to the overhead conveyor and all necessary pneumatic and electrical fittings.

| Lenght | 385 | mm |

|---|---|---|

| Width | 140 | mm |

| Height | 540 | mm |

| Air cons. | 0,7 | m³/h |

| Total weight | 77 | kg |

| Shipping volume | 0,42 | M³ |

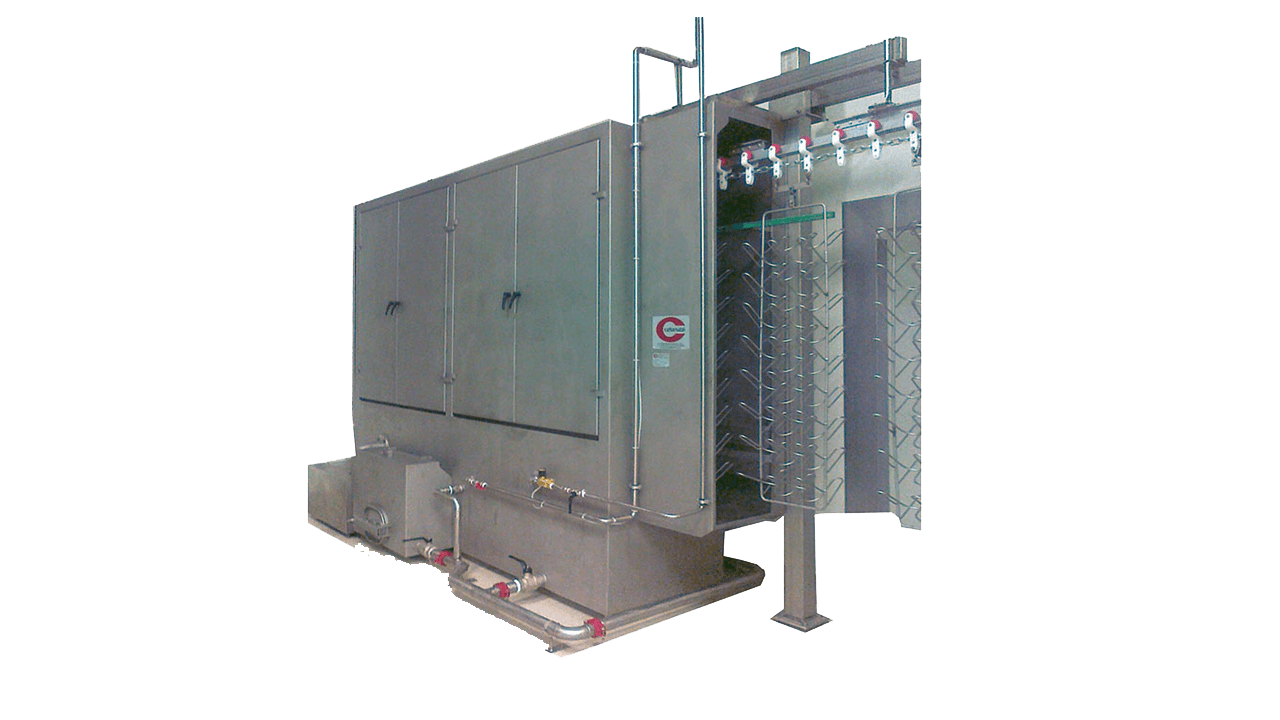

CHILLING AND WEIGHING

This unit is installed on air chiller line to wash the multi-birds shackle. The frame is in heavy stainless steel plate with side door for easy inspection. The machine is devised in two sections, in the first section we have filter, recycling water pump, in the second section we have the final cleaning with sanitary dispenser.

| Capacity | 300 | S/h |

|---|---|---|

| Lenght | 4.000 | mm |

| Width | 1.200 | mm |

| Height | 2.360 | mm |

| Water cons. at 3 bar | 0,5 | m³/h |

| Power installed | 10 | kw |

| Total weight | 900 | kg |

| Shipping volume | 9,6 | M³ |

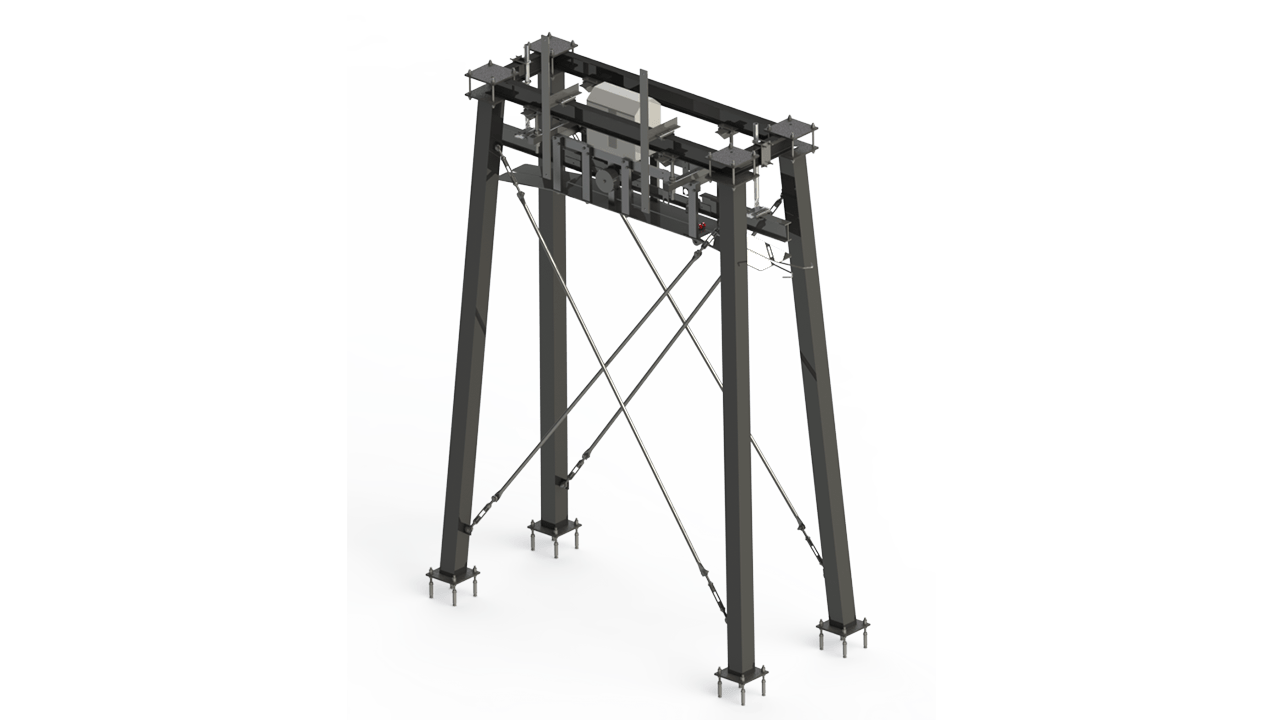

CHILLING AND WEIGHING

The distribution boxes overhead conveyor has been designed to carry the boxes used for packing into the different areas of the processing plant. This reduce the labor cost to manually carry the boxes or the plastic trays, save space on the floor and keep the production paces. Special hooks are available to carry any kind of box or tray.

CHILLING AND WEIGHING

This trolley is used to carry the birds inside the chilling room. The frame is made of stainless steel with mounted four wheels. The trolley has a capacity of 190 birds.

| Capacity | 190 | q |

|---|---|---|

| Lenght | 1.500 | mm |

| Width | 800 | mm |

| Height | 1.600 | mm |

| Total weight | 80 | kg |

| Shipping volume | 0,6 | M³ |

QUESTIONS?

Are you looking forward to start your new project?

Contact us and we will find the right solution for you.