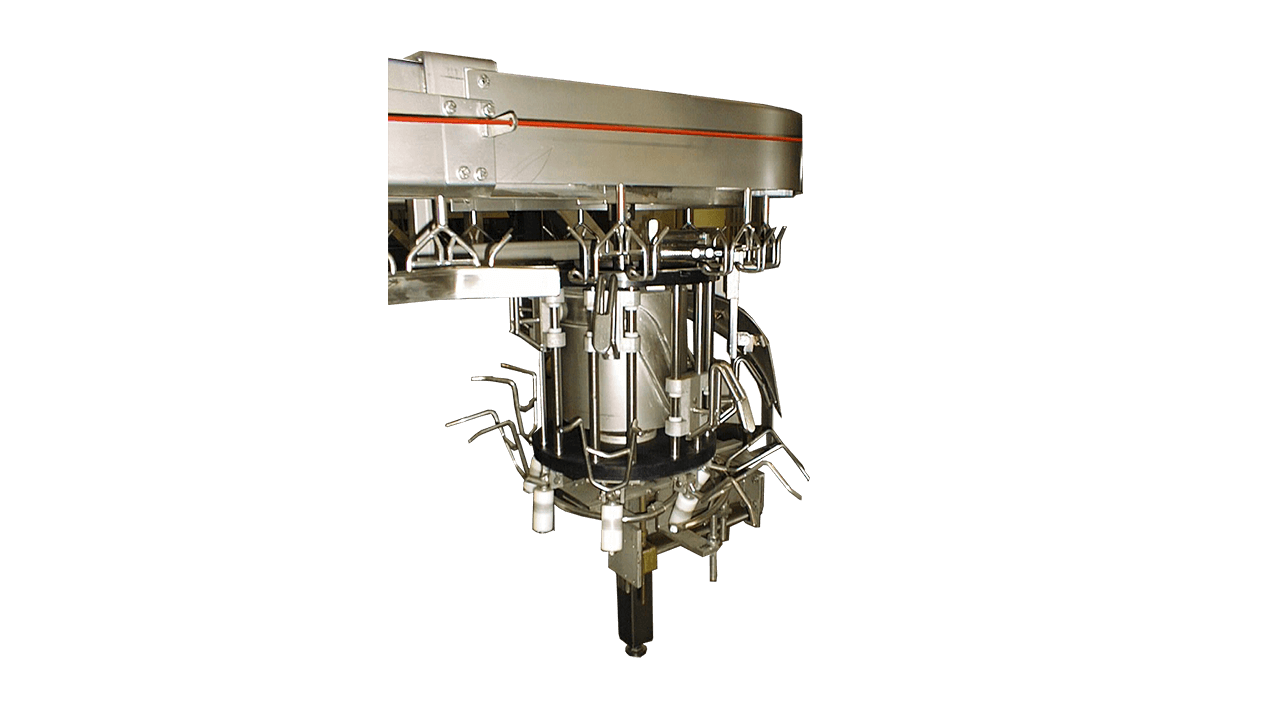

CUT-UP

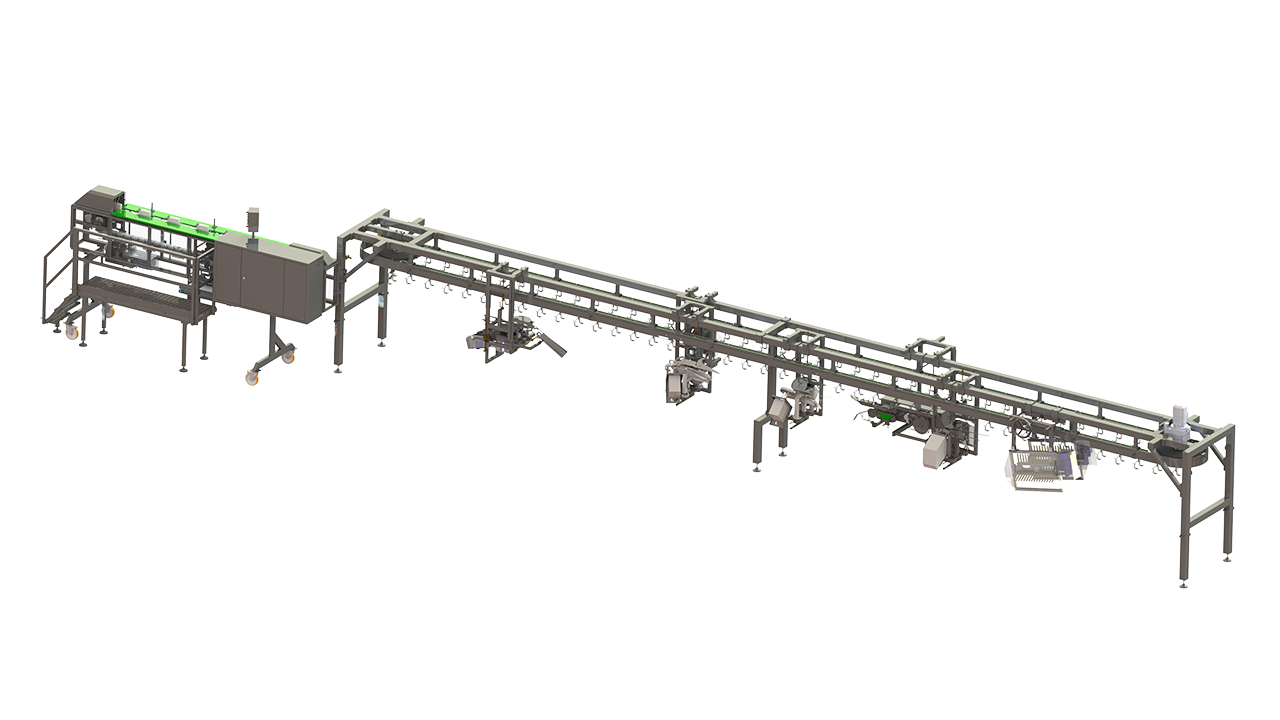

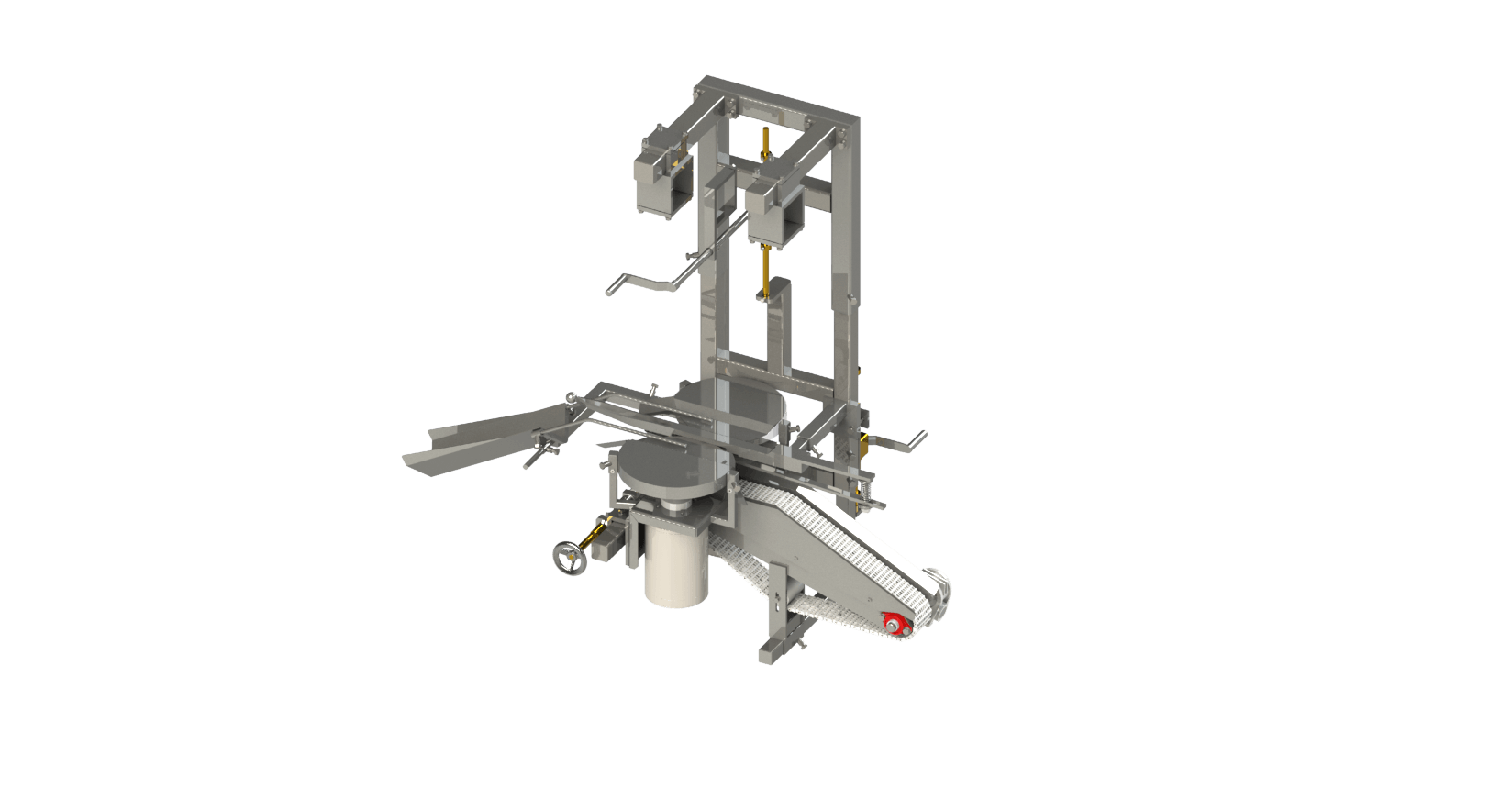

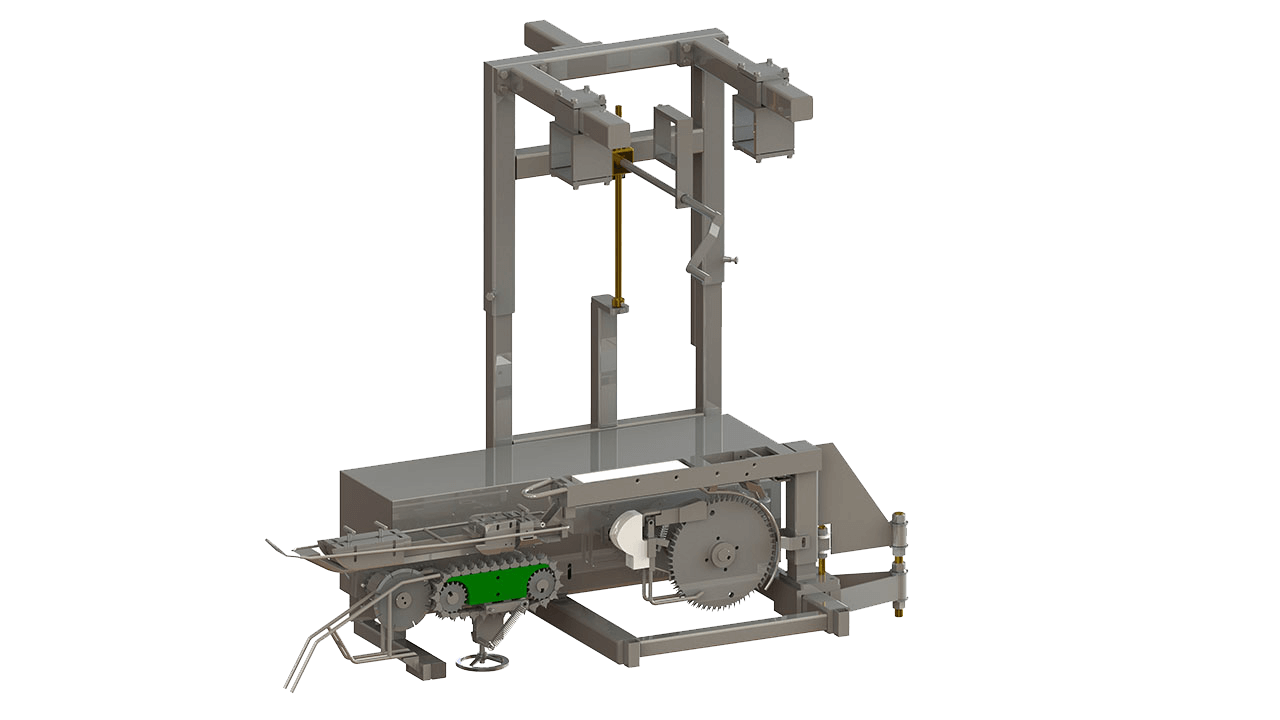

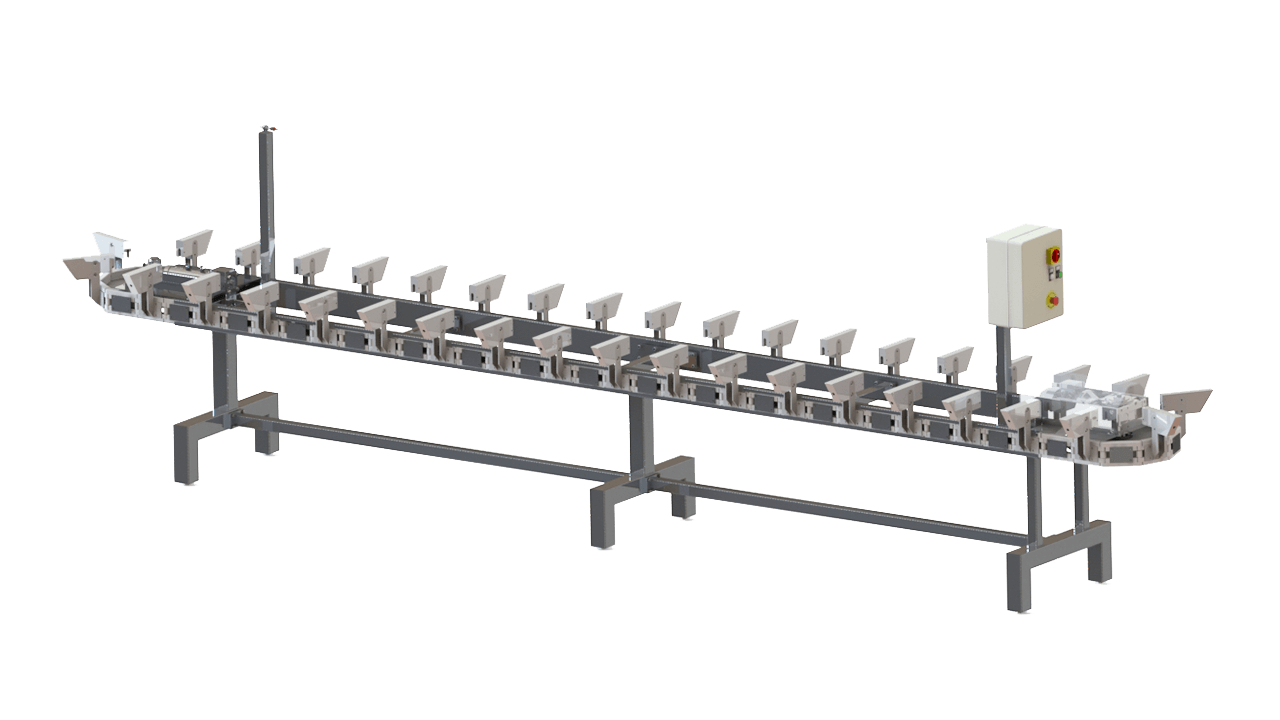

The cut up line model “COMPACT” consists of a stainless steel frame on which are installed the cutup modules to be used for automatic cut up of chickens. To get the best yield the weight difference in the flock cannot exceed 500 gr. All the portioning machines fitted on the line can be adjusted . The standard line is 5,5 m. long and it is supplied with drive, tension unit, stainless steel shackles, electric control panel and safety device. Upon request and according to the nomber of cuts required, the line can be estended up to 16,5 m.

| Capacity | 6.000 | B/h |

|---|---|---|

| Lenght | 5.500 | mm |

| Width | 1.285 | mm |

| Height | 2.300 | mm |

| Power installed | 1,1 ÷ 1,5 | kw |

| Total weight | 550 | kg |

| Shipping volume | 8,5 | M³ |

CUT-UP

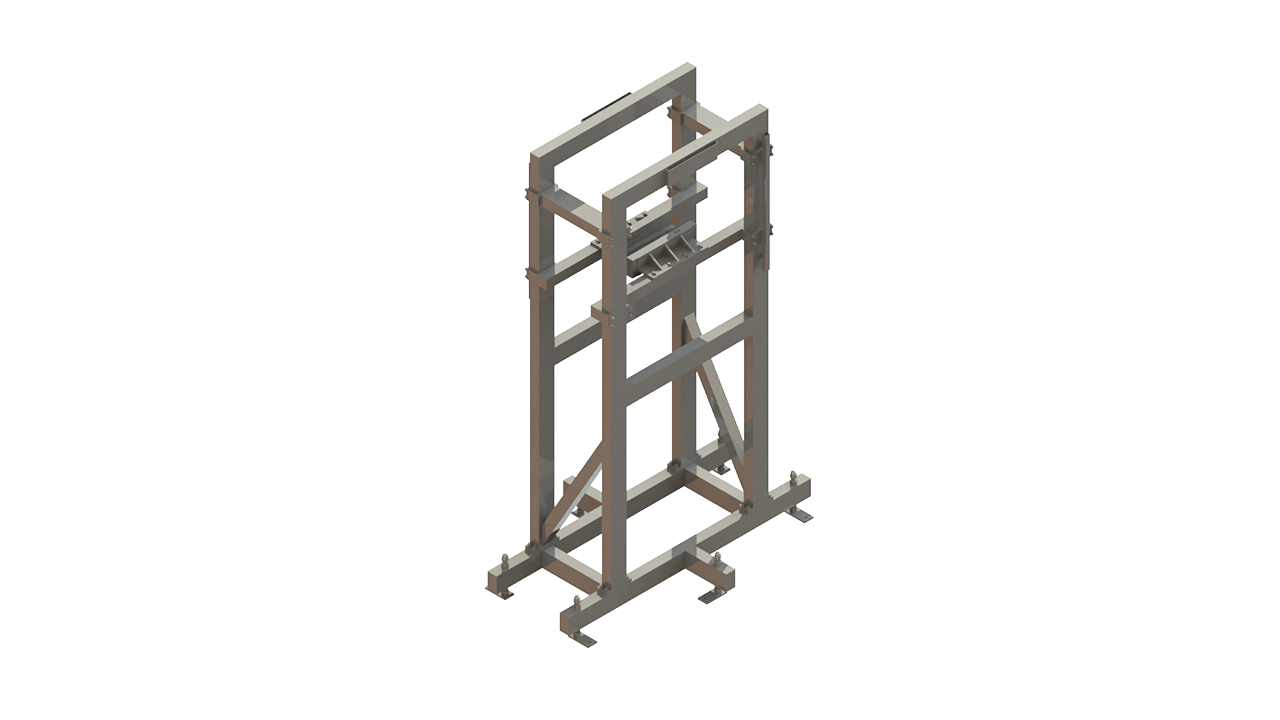

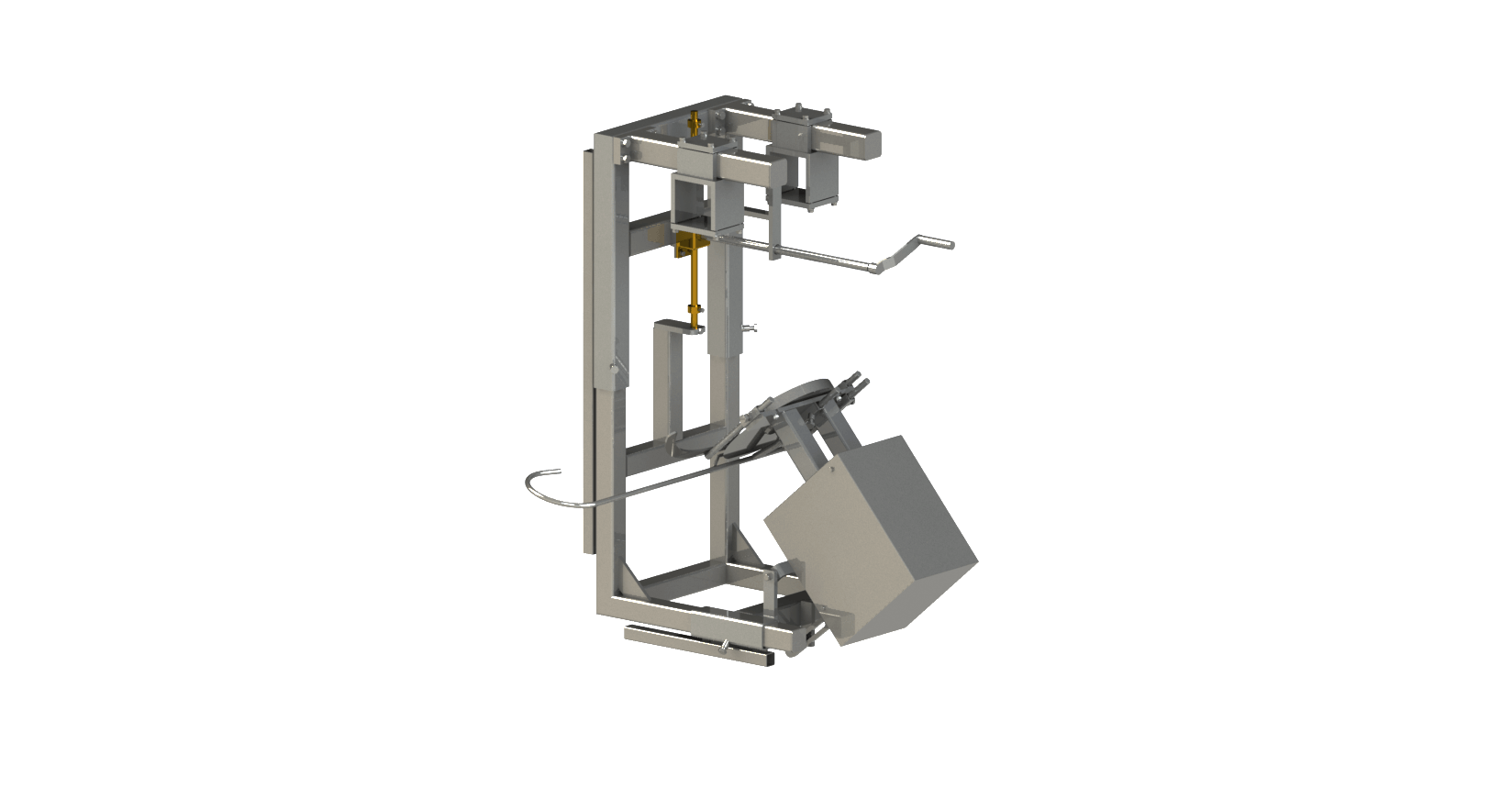

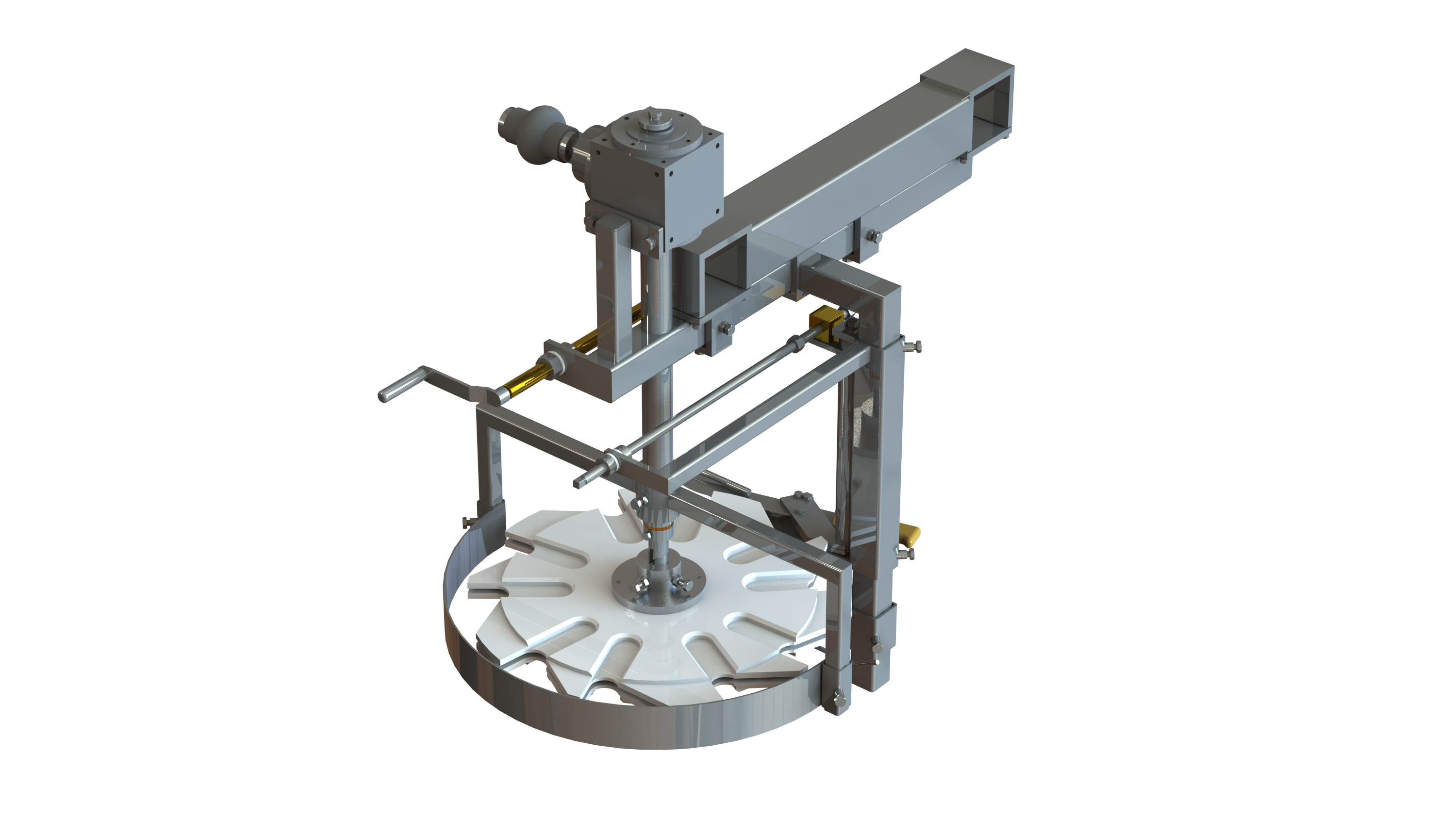

The weighing bridge is complete with a weighing cell, weight transmitter, wiring and all sensor needed. The frame is made of stainless steel.

| Lenght | 1.550 | mm |

|---|---|---|

| Width | 1.050 | mm |

| Height | 2.500 | mm |

| Total weight | 200 | kg |

| Shipping volume | 1 | M³ |

CUT-UP

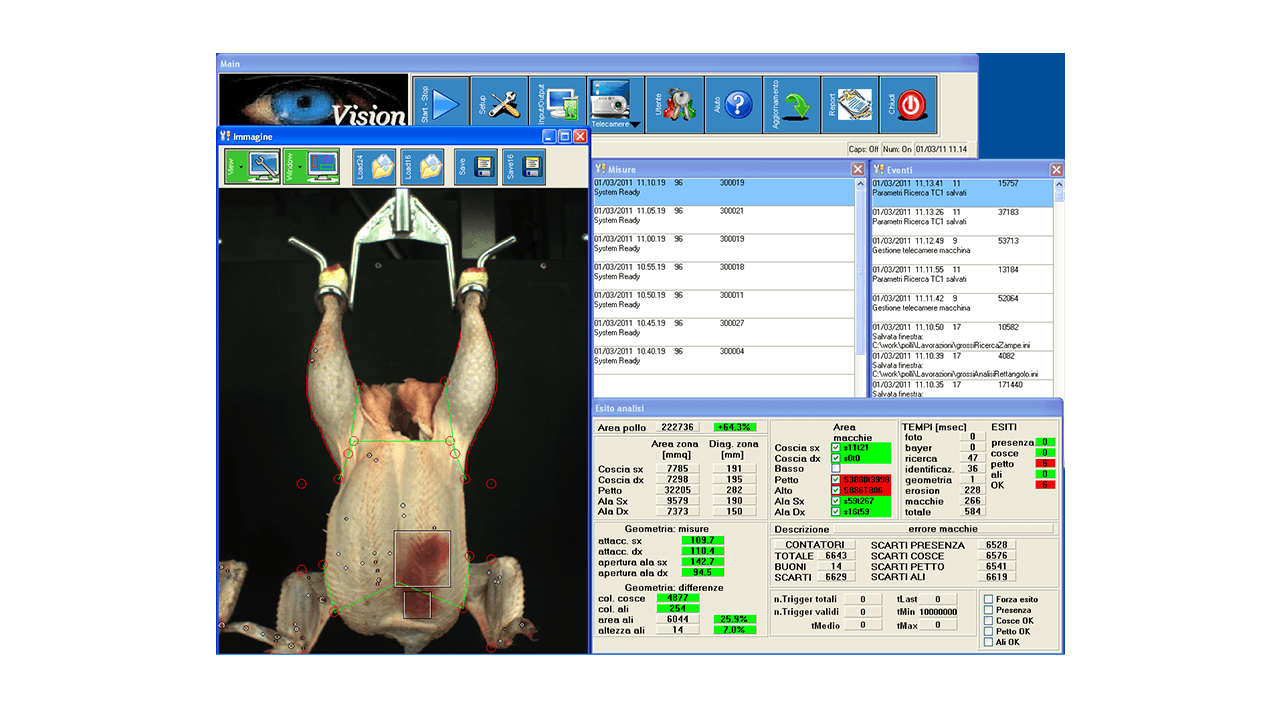

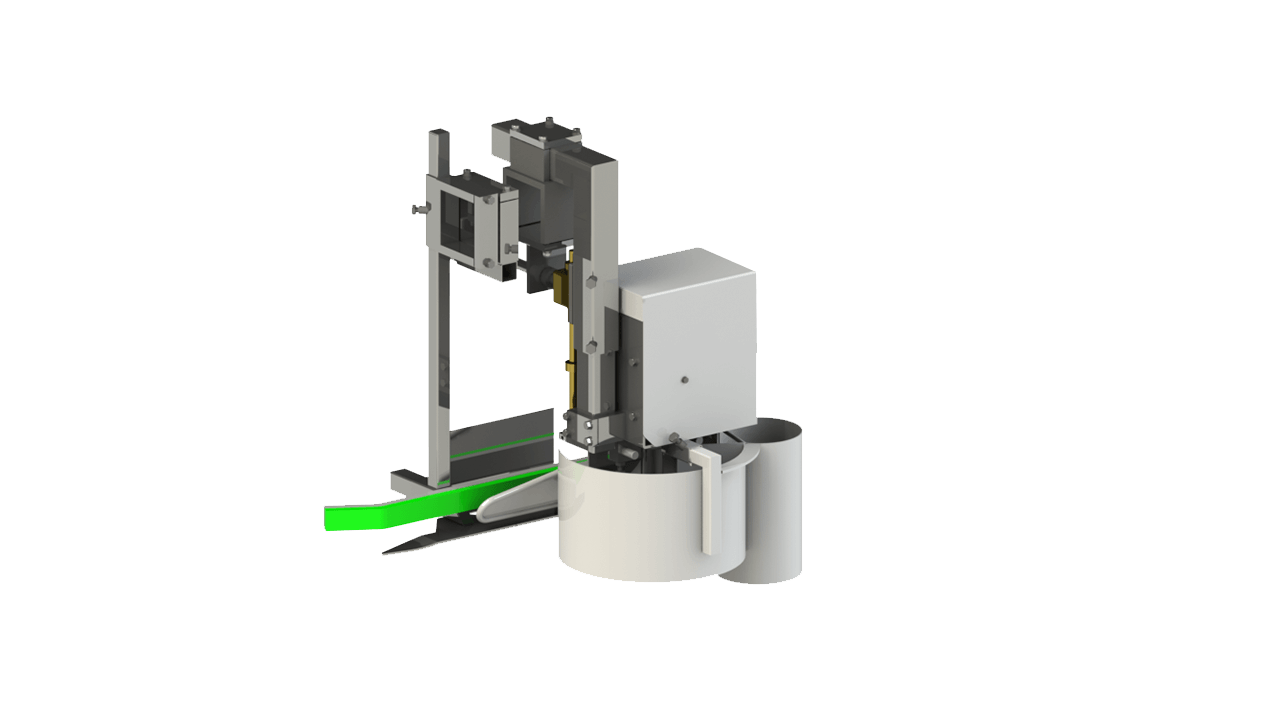

CONTROL QUALITY FOR CUT-UP LINE – The vision system inspects and grades poultries analyzing visible quality in cut up line, while the birds hook to the shackles, pass in front of a digital camera. The bird is divided in three parts, separately checked by the system: legs, wings and breast. For each of these parts system checks the presence of blood spot (red) and if the spot area is over a settable threshold, the part is graded as B. Moreover system checks also wings integrity. In case of partial or total broken bones the wings are graded B as well. A signal coming to the camera from a photocell triggers image acquisition and image processing starts immediately.

CUT-UP

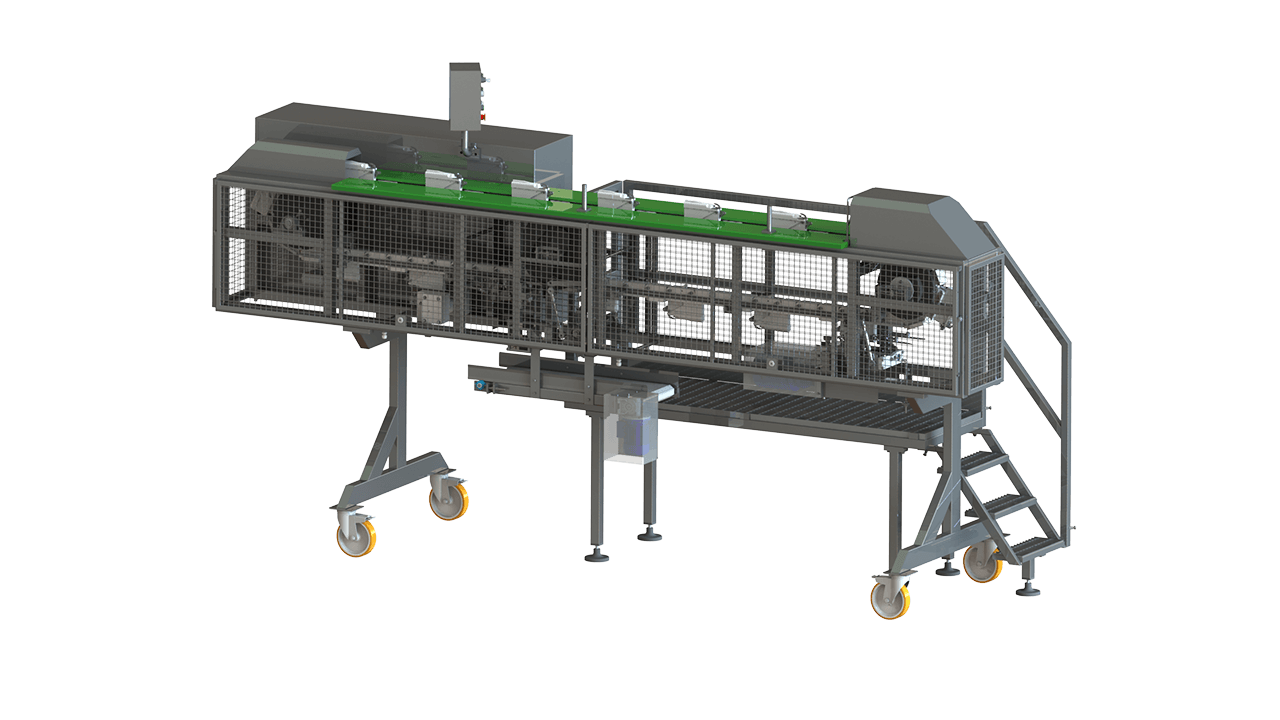

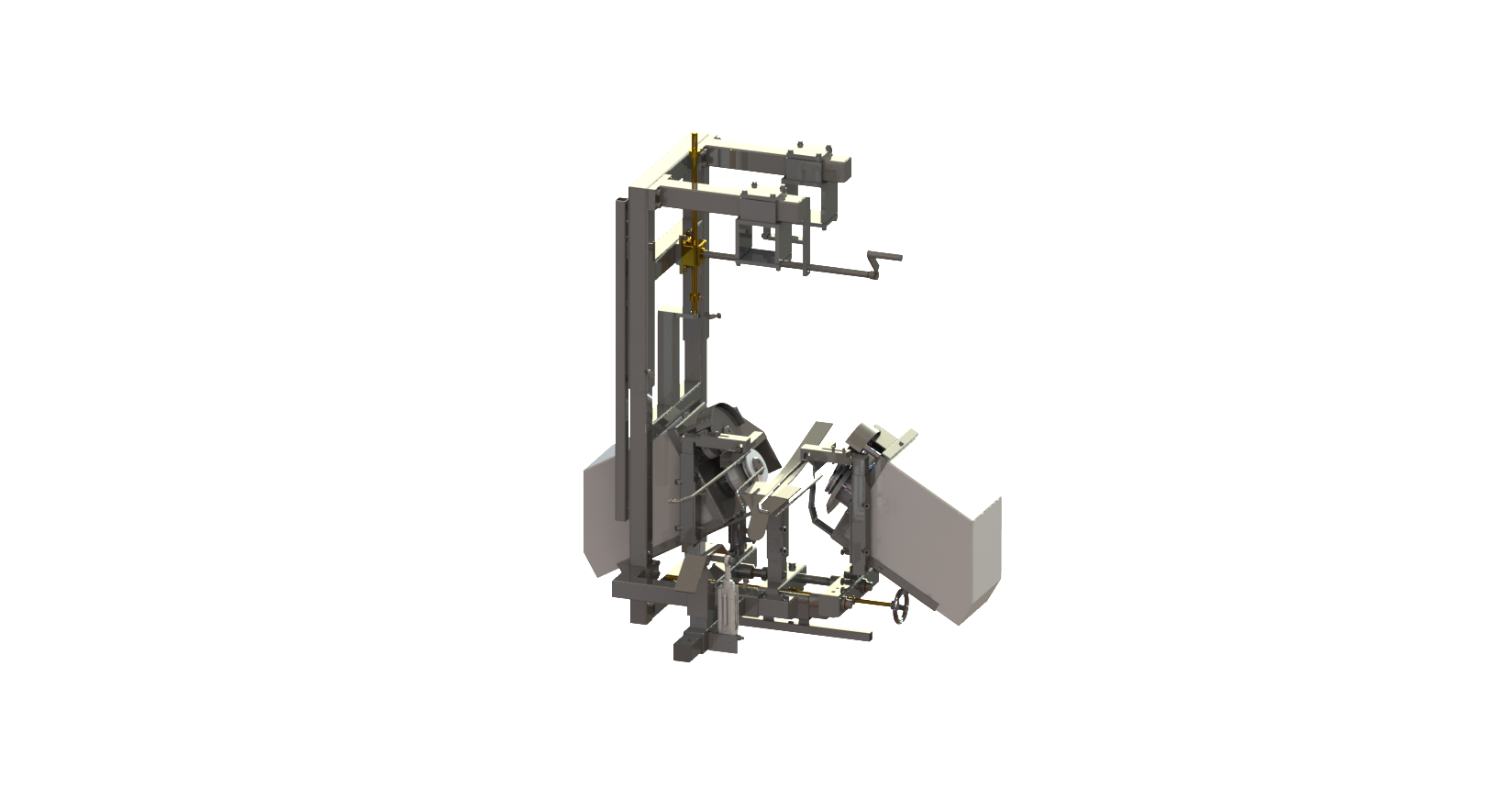

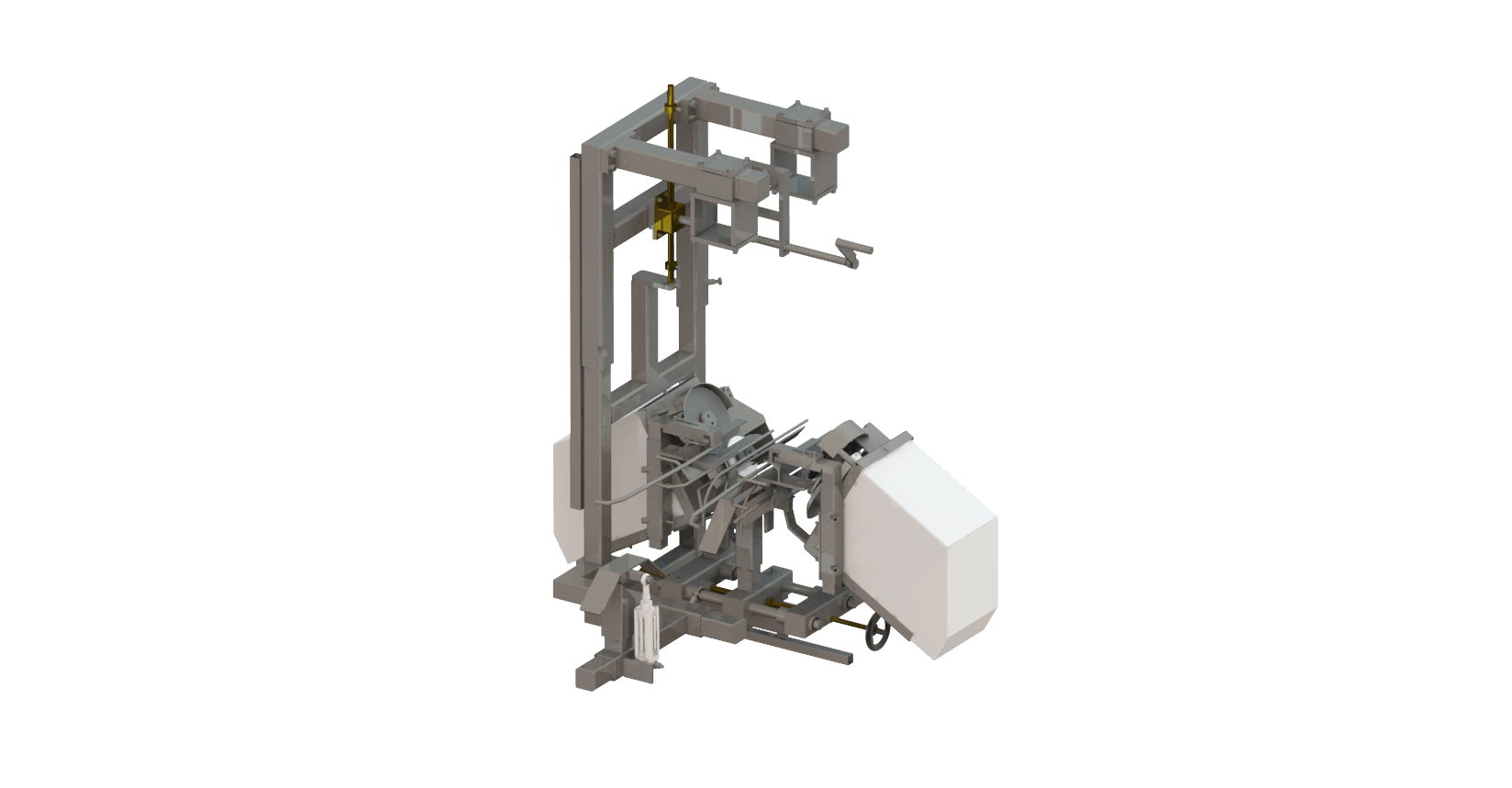

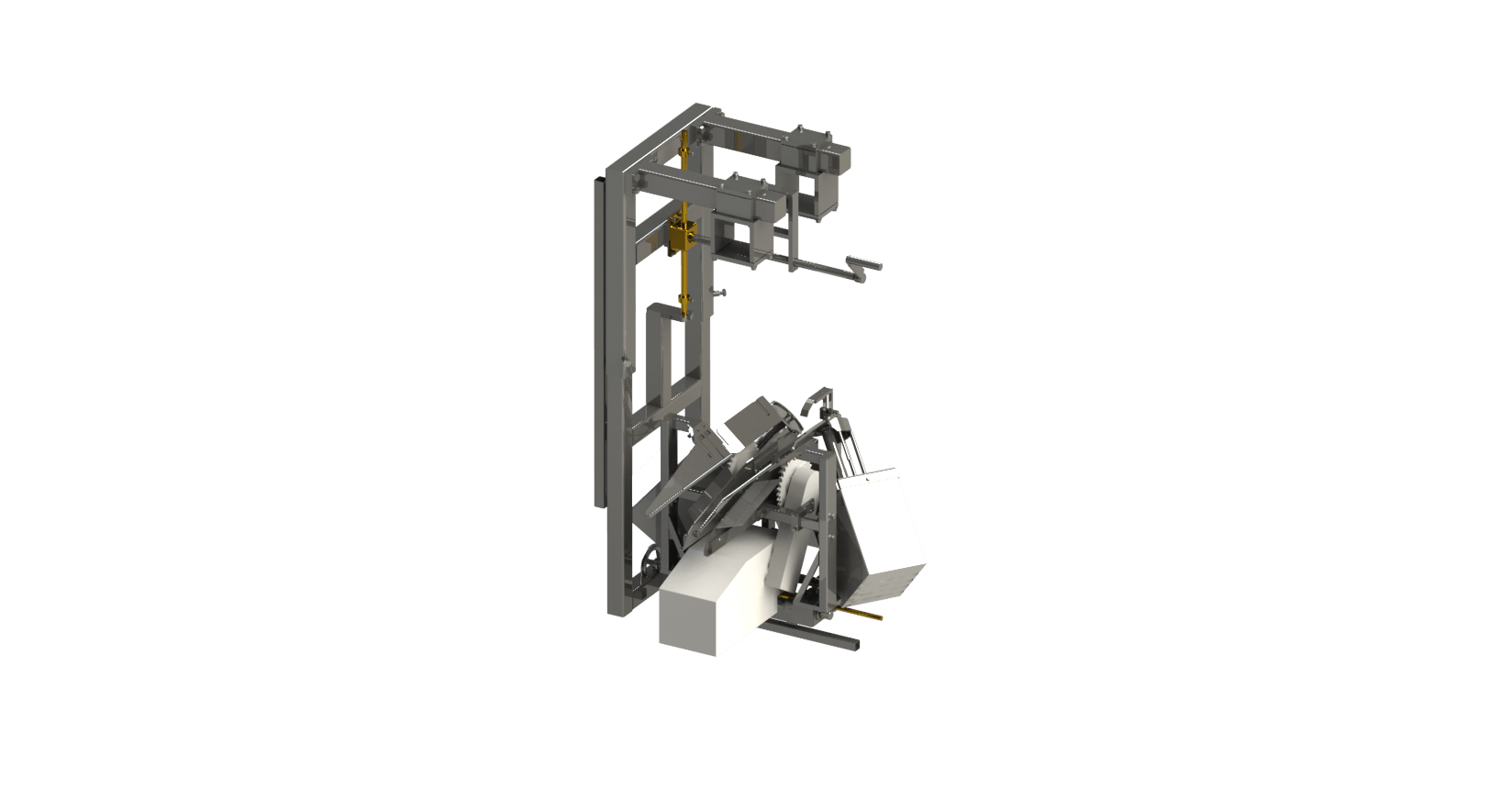

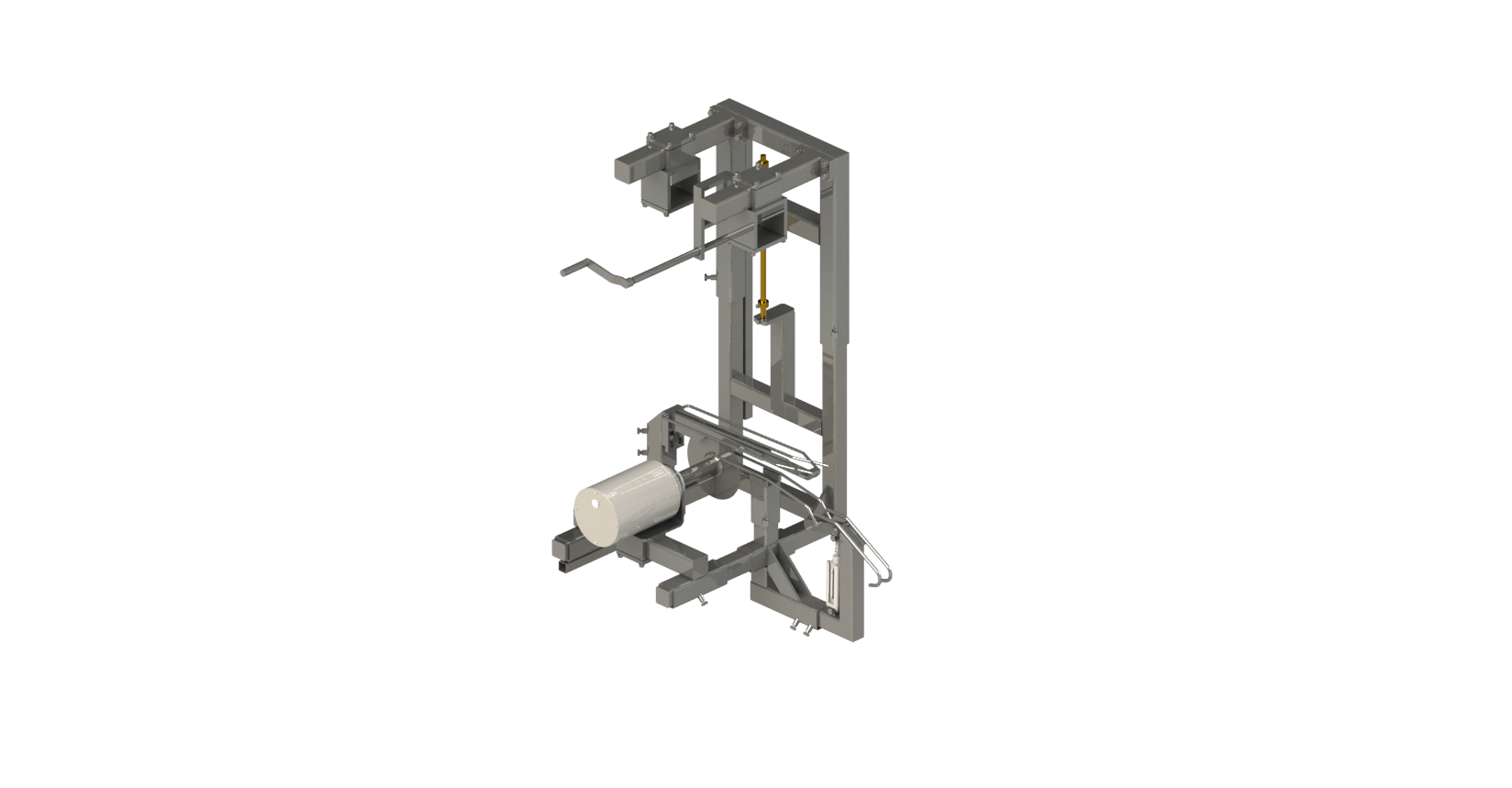

The automatic breast filleting machine C15 is specially developed to debone the breast caps. The machine is manually loaded and operates mechanically. On the machine can be add two extra modules, an automatic deskinning unit and a half breast two blades splitter. To get the best yield the weight difference of the birds in the flock cannot exceed 500gr and the cap should be cut at the wings joint. The machine is made of stainless steel and food approoved PVC. The breast deboner is complete with electric control panel, safety device and CE certificate.

| Capacity | 2.500 | B/h |

|---|---|---|

| Lenght | 3.700 | mm |

| Width | 1.050 | mm |

| Height | 2.000 | mm |

| Power installed | 2 | kw |

| Total weight | 900 | kg |

| Shipping volume | 6 | M³ |

CUT-UP

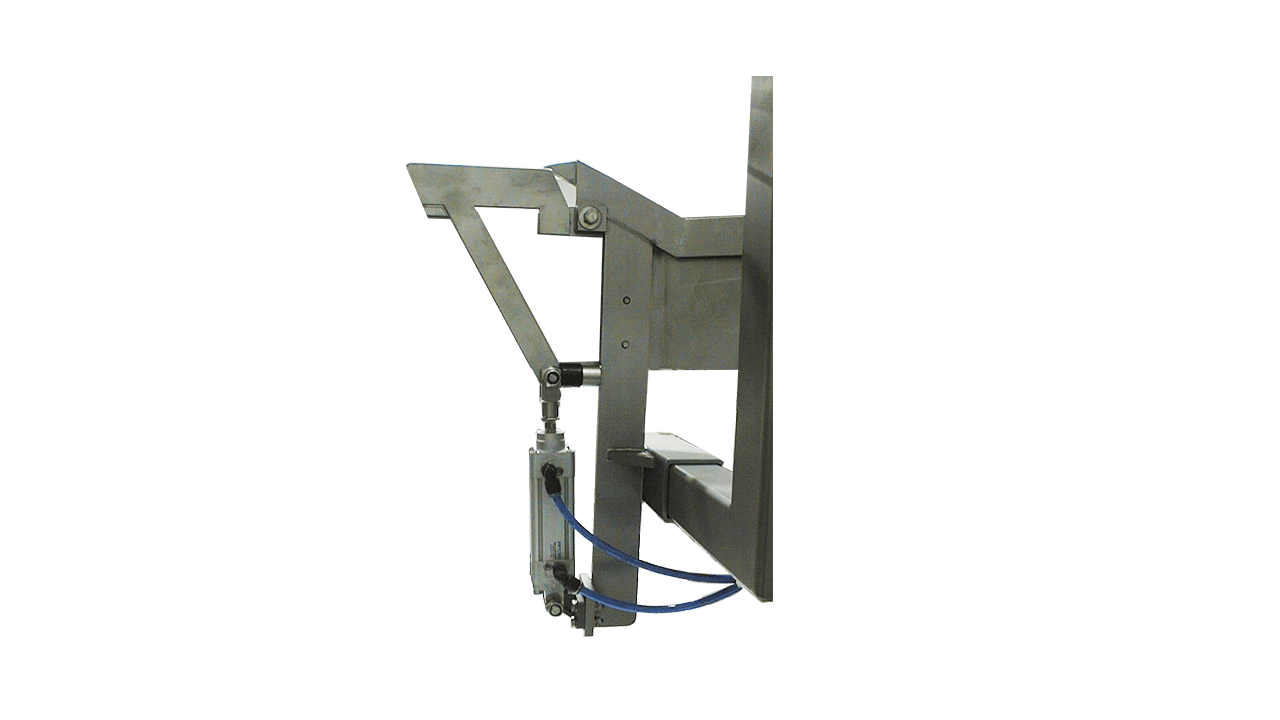

Used to cut the chicken vent across. The machine is driven by the overhead conveyor. The opening is made by an adjustable static blade. The machine is made of stainless steel.

| Height | 900 | mm |

|---|---|---|

| Total weight | 130 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used to cut off the wing tip through the joint. The machine is mounted on the cut-up line and it is manually adjustable in height and width. The cut is achieved thanks to two rotating blades. Each blade is controlled by an electric motor and protected with a proper guard. To get the best yield the weight difference in the flock cannot exceed 500gr The machine is made of stainless steel.

| Lenght | 1.000 | mm |

|---|---|---|

| Width | 600 | mm |

| Height | 815 | mm |

| Power installed | 1,5 (2 motors) | kw |

| Total weight | 75 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used to cut off the wing part through the second joint, thanks to two circular blades which are easily adjustable in height and width. The machine is stainless steel.

| Lenght | 1.000 | mm |

|---|---|---|

| Width | 600 | mm |

| Height | 815 | mm |

| Power installed | 1,5 (2 motors) | kw |

| Total weight | 75 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used to cut anatomically, at the joint the wings of the chicken. The machine is mounted on the cut-up line and it is manually adjustable in height and width. The cut is achieved thanks to two rotating blades. Each blade is controlled by an electric motor and protected with a proper guard. To get the best yield the weight difference in the flock cannot exceed 500gr The machine is made of stainless steel.

| Lenght | 1.000 | mm |

|---|---|---|

| Width | 840 | mm |

| Height | 815 | mm |

| Power installed | 1,5 (2 motors) | kw |

| Total weight | 85 | kg |

| Shipping volume | 0,2 | M³ |

CUT-UP

Installed on the cut-up line cuts the front part of the chicken (breast with bone). The cut is achieved through two rotating blades driven by electric motors, while the chicken is kept perfectly positioned by some guards. To get the best yield the weight difference in the flock cannot exceed 500gr The machine is stainless steel.

| Lenght | 1.000 | mm |

|---|---|---|

| Width | 840 | mm |

| Height | 815 | mm |

| Power installed | 1,87 (3 motors) | kw |

| Total weight | 95 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used to cut the backbone after the front piece cutter. The cut is achieved through a rotating blade driven by electric motor. To get the best yield the weight difference in the flock cannot exceed 500gr. The machine is adjustable in height and made off stainless steel.

| Power installed | 0,75 | kw |

|---|---|---|

| Total weight | 65 | kg |

| Shipping volume | 0,2 | M³ |

CUT-UP

This machine trims the hocks of the birds to have a better presentation of the product. It is built in stainless steel and it is height adjustable.

| Lenght | 500 | mm |

|---|---|---|

| Width | 400 | mm |

| Height | 400 | mm |

| Power installed | 0,75 | kw |

| Total weight | 55 | kg |

| Shipping volume | 0,2 | M³ |

CUT-UP

Used to split the saddle either with the backbone or without (two blades cut). The cut is achieved through a rotating blade, driven by electric motor, (double blades in case of saddle without backbone) which split the saddle. To get the best yield the weight difference in the flock cannot exceed 500gr The machine is made of stainless steel.

| Lenght | 800 | mm |

|---|---|---|

| Width | 500 | mm |

| Height | 700 | mm |

| Power installed | 0,37 | kw |

| Total weight | 65 | kg |

| Shipping volume | 0,3 | M³ |

CUT-UP

Used to anatomically remove the two whole legs from the back saddle. The machine is installed on the cut-up line and it operates through some fixed blades, and wheel pulling the legs. The oyster remains attached to the thigh. The machine is made of stainless steel and it is supplied with drive unit and variable speed frequency converter.

| Lenght | 1.000 | mm |

|---|---|---|

| Width | 500 | mm |

| Height | 700 | mm |

| Power installed | 1,1 | kw |

| Total weight | 120 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used to split drumsticks from the tight chicken legs. Thighs automatically fall down and only drumsticks remain hung on the shackles. The drumstick/thigh separation is achieved thanks to a steady blade and a rotating wheel that is synchronized with the line speed. Thanks to its special design, the wheel holds the leg in the anatomic position to make an easier joint cut. All stainless steel and nylon.

| Lenght | 700 | mm |

|---|---|---|

| Width | 450 | mm |

| Height | 700 | mm |

| Total weight | 80 | kg |

| Shipping volume | 0,5 | M³ |

CUT-UP

Used for the automatic unloading of drumsticks/legs from the shackles. Made of stainless steel, this unit is installed on the cut up line.

| Total weight | 8 | kg |

|---|---|---|

| Shipping volume | 0,01 | M³ |

CUT-UP

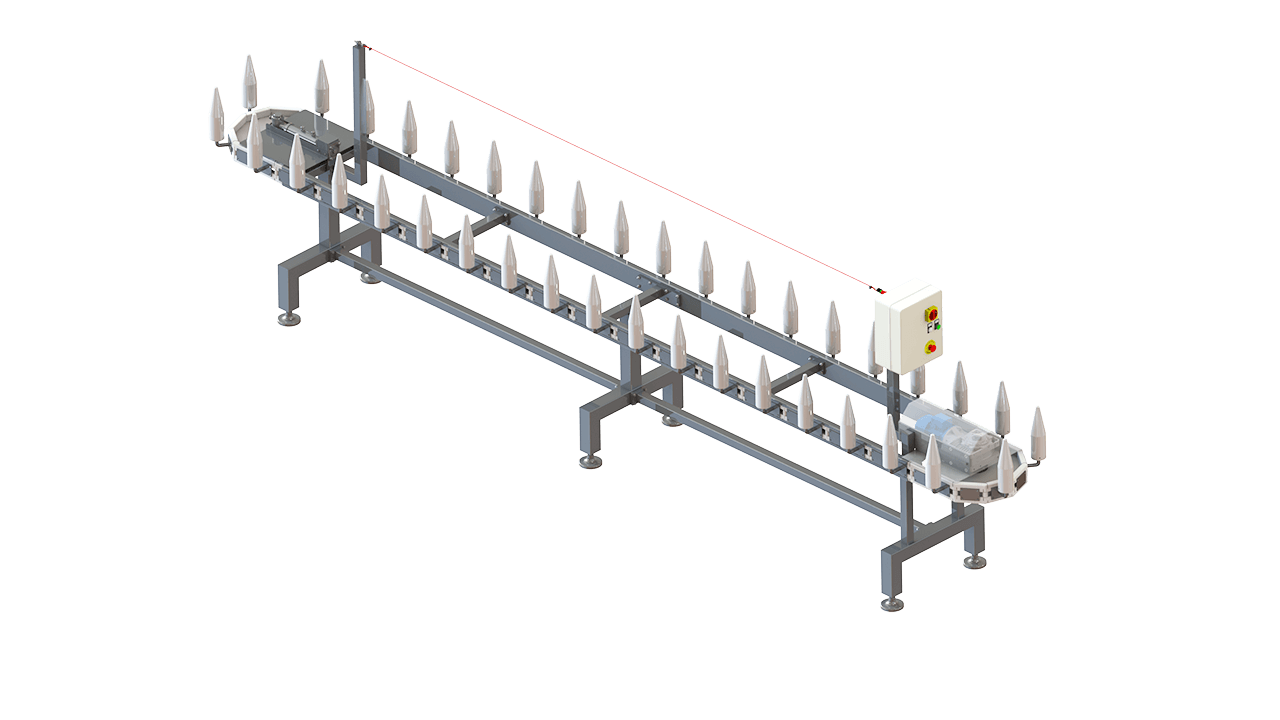

The cones cut up line used for cutting and deboning the chickens is complete with electrical panel, securities and CE certification. the lenght of the line can be extended to increase the capacity. The frame is made of stainless steel and the cones in PVC food approved.

| Capacity | 1.000 | B/h |

|---|---|---|

| Lenght | 5.720 | mm |

| Width | 750 | mm |

| Height | 1.200 | mm |

| Power installed | 0,37 | kw |

| Total weight | 310 | kg |

| Shipping volume | 3,5 | M³ |

CUT-UP

Manual chicken deboning line with cones for breast cap complete with control panel and safety device. It is made of stainless steel and heavy duty nylon. The line is 5.6 mt. long with cones at 300 mm pitch. The operator can work on both site of the line.

| Capacity | 1.000 | B/h |

|---|---|---|

| Lenght | 5.720 | mm |

| Width | 750 | mm |

| Height | 1.200 | mm |

| Power installed | 0,37 | kw |

| Total weight | 310 | kg |

| Shipping volume | 3,5 | M³ |

QUESTIONS?

Are you looking forward to start your new project?

Contact us and we will find the right solution for you.